FORM NO. 56043051 / Retriever

™

2060 - 13

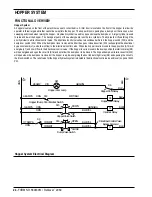

SWEEPING SYSTEM

ORN

BLK

S12

+

L3

3.8 AMPS

WHT/BLU

23 W

1

2

S13

ORN/GRN

BLK

L4

WHT/BLU

23 W

1

2

S14

YEL/BRN

_

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

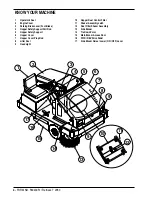

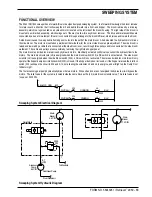

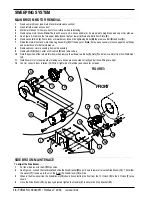

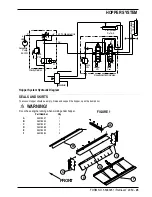

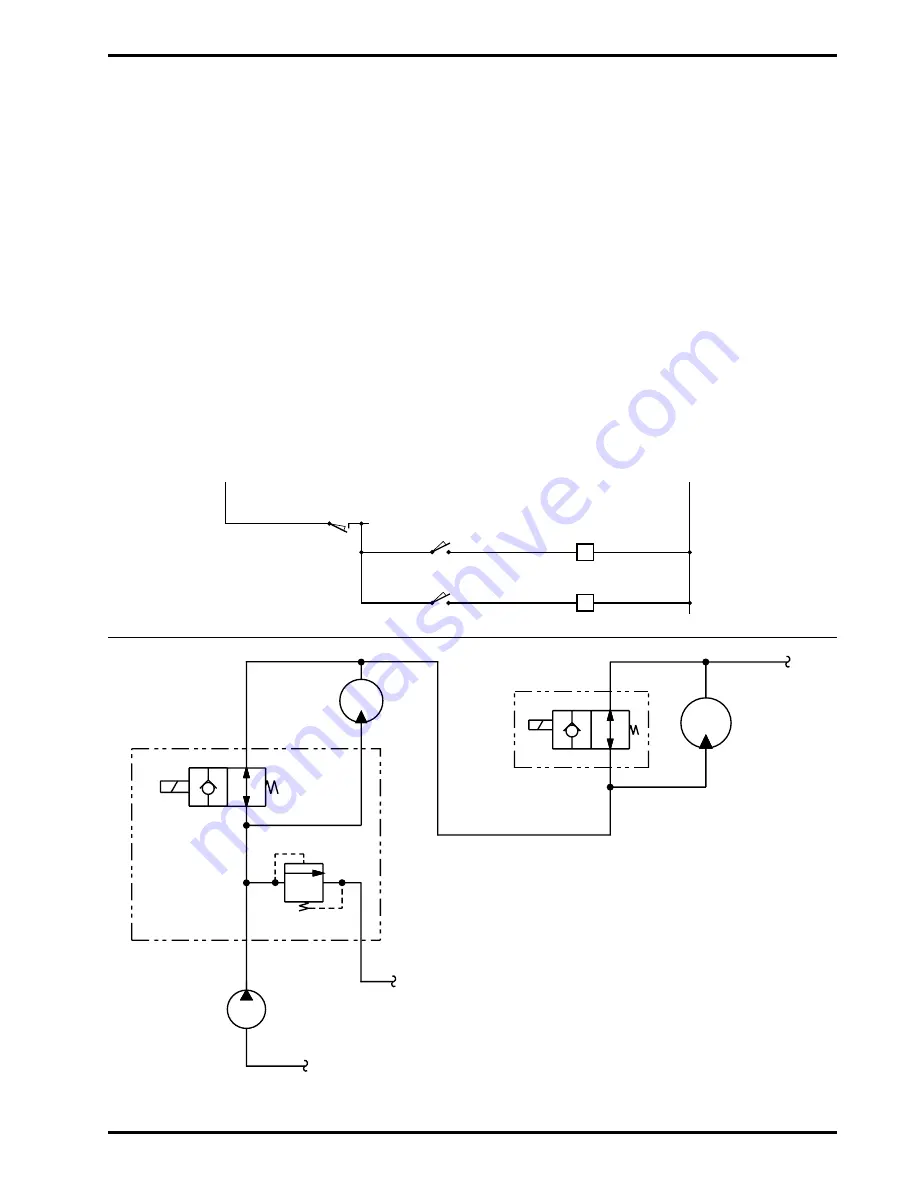

FUNCTIONAL OVERVIEW

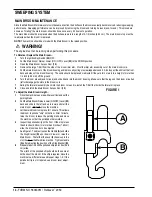

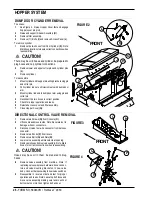

The 2060 / SR 1800 sweeper has a forward-throw or dustpan designed sweeping system. In a forward throw design the broom is made

to rotate in such a direction that it will sweep the dirt and debris forward into a front-end hopper. The broom is driven by a drive lug

assembly, which is a lug mounted on a hydraulic motor, located on the left side of the broom housing. The right side of the broom is

mounted to an idler hub assembly, which swings out of the way to allow for easy broom removal. The drive and idler assemblies are

connected by a hex arm weldment, this arm is connected through a linkage to the broom lift lever, which raises and lowers the broom.

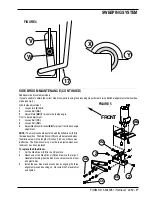

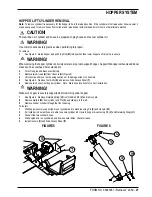

A side broom is used to sweep debris from edges or curbs into the path of the main broom. A hub mounted to a hydraulic motor drives

the side broom. The motor is mounted on a weldment that will allow for the correct side broom angle adjustment. The side broom is

raised and lowered by a cable that is connected at the side broom lever, runs through three pulleys and is connected at the side broom

weldment. The cable and pulleys are accessible by removing the right side hopper panel.

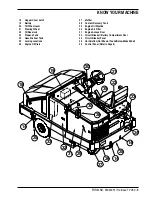

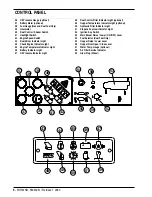

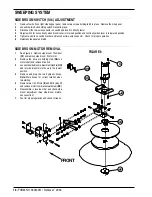

The main broom and side broom are driven by hydraulic motors. Electrically activated control valves control the hydraulic flow to the

motors. The main broom solenoid (L3) is energized when the main broom switch (S13), a NC switch is not activated. The side broom

solenoid (L4) is energized when the side broom switch (S14), a NC switch is not activated. The main and side broom motors will only

operate if the hopper dump door interlock switch (S12) is closed. If the hopper dump door is closed, or if the hopper is raised, the interlock

switch (S12) will open the circuit to S13 and S14, not allowing the solenoids L3 and L4 to energize, and will light up the Dump Door

Indicator Light.

The first accessory gear pump hydraulically drives the two motors. When L3 and L4 are not energized the hydraulic oil will bypass the

motors. The relief valve for the system is located inside the same block as the (L3) main broom solenoid valve. This relief valve is set

to open at 2500 PSI.

Sweeping System Electrical Diagram

Sweeping System Hydraulic Diagram

Dual Gear Pump

Accessory

Pump

.84 CIR

P

T

8.7

GPM

2500

PSI

B

A

Relief Block

L3

Main

Broom

4.5 CIR

L4

Side

Broom

17.9 CIR

To Manifold

From Reservoir

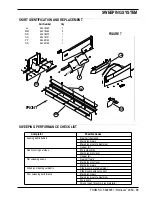

Summary of Contents for Advance Retriever 2060

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...