FORM NO. 56043051 / Retriever

™

2060 - 47

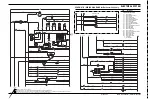

ENGINE SYSTEM

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

STARTING THE GASOLINE ENGINE

1

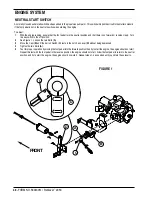

With the Engine Speed Switch (42) in the IDLE position ( l ), turn the Ignition Key Switch (52) clockwise to the START position and

release it as soon as the engine starts. If the engine does not start after cranking for 15 seconds, release the key, wait for 1 minute,

then try again.

2

Once started, let the engine run with the Throttle Control Switch in the IDLE ( l ) position for 5 minutes before using the machine.

3

Push the Throttle Control Switch to the FULL THROTTLE position ( lll )and move the machine around for 2 or 3 minutes at a slow

speed to warm up the hydraulic system.

ALWAYS operate the machine with the Throttle Control Switch at full throttle. Use the Forward/Reverse Pedal (16)

- not the Throttle Control Switch - to control the speed of the machine. The speed of the machine will increase as the pedal

is pushed closer to the floor. Do not press the Forward/Reverse Pedal until the engine has started, this will disengage the

starter if the optional Neutral Safety Switch is installed.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

STARTING THE PROPANE ENGINE

1

Open the service valve on the LP fuel tank (23).

2

With the Engine Speed Switch (42) in the IDLE position ( l ), turn the Ignition Key Switch (52) clockwise to the START position and

release it as soon as the engine starts. If the engine does not start after cranking for 15 seconds, release the key, wait for 1 minute,

then try again.

3

Once started, let the engine run with the Throttle Control Switch in the IDLE position ( l ) for 5 minutes before using the machine.

4

Push the Throttle Control Switch to the FULL THROTTLE position ( lll ) and move the machine around for 2 or 3 minutes at a slow

speed to warm up the hydraulic system.

ALWAYS operate the machine with the Throttle Control Switch at full throttle. Use the Forward/Reverse Pedal (16)

- not the Throttle Control Switch - to control the speed of the machine. The speed of the machine will increase as the pedal

is pushed closer to the floor. Do not press the Forward/Reverse Pedal until the engine has started, this will disengage the

starter if the optional Neutral Safety Switch is installed.

________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________________

STARTING THE DUAL FUEL ENGINE

1

The machine can be started using either fuel.

2

Select the desired fuel (54) and follow the starting procedure for that fuel.

3

In cold environments (below 32 degrees F / 0 degrees C) starting the unit on gasoline is recommended.

ALWAYS operate the machine with the Throttle Control Switch at full throttle. Use the Forward/Reverse Pedal (16)

- not the Throttle Control Switch - to control the speed of the machine. The speed of the machine will increase as the pedal

is pushed closer to the floor. Do not press the Forward/Reverse Pedal until the engine has started, this will disengage the

starter if the optional Neutral Safety Switch is installed.

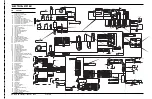

Summary of Contents for Advance Retriever 2060

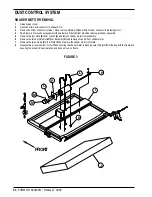

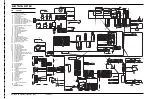

Page 87: ...4 99 Form No 56040696 page 2 A 3 B C D 5 1 2 6...

Page 94: ...6 99 revised 3 00 Form No 56040702 page 2 5 3 2 6 6 5 3 4 1 2...

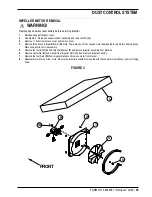

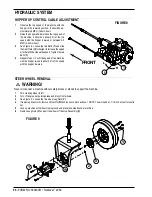

Page 111: ...9 00 Form No 56040733 page 2 of 3 Diesel H FRONT M K L N R W P O T S J Q O P U V FIGURE 1...

Page 128: ...PROGRAM PURPOSE and OBJECT ZENITH FUEL SYSTEMS Page 1 1 5 48 7 0 1 2 3 4 5 0 50...

Page 133: ...ZENITH FUEL SYSTEMS Page 5 1 5 0 50 A 50 4 4 B 8 6 A C D FIG 5 1...

Page 134: ...ZENITH FUEL SYSTEMS Page 5 2 6 5 8 0 8 2 0 2 0 2 E F 0 D 50 4 C D 5 5 5 5 6 6 2 0 6 FIG 5 2...

Page 139: ...Fuel Enrichment 4 6 6 50 5 5 6 A 50 5 0 0 ZENITH FUEL SYSTEMS Page 5 7...

Page 144: ...ZENITH FUEL SYSTEMS INC Page 5 12 3F 6 6 H J 3F FIG 5 19 6 G 6 FIG 5 20...

Page 147: ...ZENITH FUEL SYSTEMS Page 6 2 A A 1 6 FIG 6 1...

Page 148: ...ZENITH FUEL SYSTEMS Page 6 3 5 2 3 0 0 1 4 4 B 6 6 6 4 4 3 6 6 6 9 6 6...

Page 149: ...ZENITH FUEL SYSTEMS Page 7 2 8 2...

Page 150: ...ZENITH FUEL SYSTEMS Page 7 3 8 2...

Page 153: ...ZENITH FUEL SYSTEMS Page 9 3...

Page 160: ...ZENITH FUEL SYSTEMS Page 9 11 6 6 9 8 2...

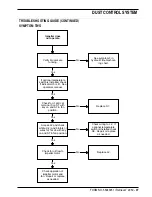

Page 163: ...ZENITH FUEL SYSTEMS Page 9 14 6 6 9 8 Continued...