FlexPAK

EN

5.3 Start the unit

For more information regarding the initial start-up,

see the ‘Installation and service manual’.

Start the unit as follows:

1

Turn the maintenance switch to position 1.

2

Compressed air connected to the unit

3

Press the Standby/Running button on the control

panel, see

item 11. The white lamp lights

up and the display shows ‘Standby’.

4

The unit starts when the test start button is

pressed,

opened at a workstation.

Always switch off the unit at the end of the shift

by pressing the Standby/Running button on the

control panel, or use the weekly timer, see

5.4 Unit operation modes

FlexPAK has the following four operation modes:

1

Off mode

2

Standby mode

3

Running mode

4

Idling mode

See

for more information

about each mode.

How the unit moves from one operation mode to an-

other is explained below. See also

chart showing how the unit goes through its four dif-

ferent operation modes.

As discussed in

, when the

unit is in Off mode, the unit can be put into Standby

mode with its motor off and the Filter Cleaning Valve

(FCV) closed by pressing the Standby/Running but-

ton. While the unit is in Standby mode, the unit can be

put back into Off mode again by pressing the Standby/

Running button.

The unit goes from Standby mode into Running

mode when it receives a pilot signal by a valve being

opened at one or more work stations (in other words,

someone starts to work). The unit’s motor is now on

and the FCV is closed. The DIR_Time and SSR_Time

timers are not started, see

The unit stays in Running mode as long as there is an

active pilot signal. However, the unit can still be put

into Off mode by pressing the Standby/Running but-

ton.

Note that if only one workstation is connected to the

unit, or if only one work station is in use and work

stops at that one station, the pilot signal stops. If

there is more than one work station connected to the

unit, and more than one work station is in use, the pi-

lot signal only stops if work stops at all workstations

(in other words, all valves close).

When the pilot signal stops, the DIR and SSR timers

start. If work resumes at one or more work stations

within 10 seconds, the unit stays in Running mode.

The DIR and SSR timers are reset back to zero and are

stopped.

If DIR_Time is set for 10 seconds (default), and the

pause in work is longer than 10 seconds, DIR_Time

elapses. The unit then goes into Idling mode with its

motor on and the FCV open.

If a new pilot signal is sent within 12 minutes, the unit

goes back into Running mode. The DIR and SSR timers

are again reset to zero and are stopped. However,

if SSR_Time is set for 12 minutes, which is the de-

fault setting, and there is no new pilot signal within 12

minutes, SSR_Time also elapses.

The unit then goes into Standby mode until it either

receives a new pilot signal that puts the unit back

into Running mode, or the unit is turned off (in oth-

er words, put into Off mode) by the weekly timer,

see ‘

Standby/Running button.

6 PLC messages

The following sections show the different status, warning and alarm messages that can be seen in the PLC dis-

play. See also the PLC Settings Manual and the Installation and Service Manual.

NOTE!

• If a message is displayed that is not shown in this user manual, see the PLC Settings Manual for more

information.

• If a warning or alarm is displayed that is not shown in this user manual, see the PLC Settings Manual for

more information and contact a Nederman authorized service technician.

6.1 Status messages

The following status messages give information about what mode the unit is in or what routine service is being

performed.

26

Summary of Contents for FlexPAK Standard

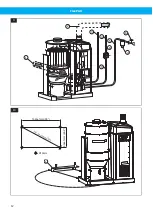

Page 9: ...FlexPAK 13 12 10 9 7 8 2 1 3 4 6 5 11 3 11 7 8 9 12 13 15 14 18 19 10 17 4 16 15 20 5 9...

Page 10: ...FlexPAK 6 1 2 3 6 7 8 9 16 15 14 13 11 10 12 4 5 7 10...

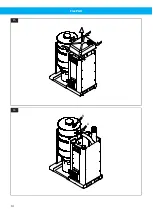

Page 12: ...FlexPAK 2 1 4 5 6 8 7 9 3 9 1 1643 1mm 65 662 1mm 26 2 1771 4 1mm 70 13mm 10 12...

Page 13: ...FlexPAK 11 12 13 14 13...

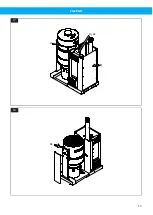

Page 14: ...FlexPAK 15 A B 16 14...

Page 15: ...FlexPAK A B C 4x 17 8x 18 15...

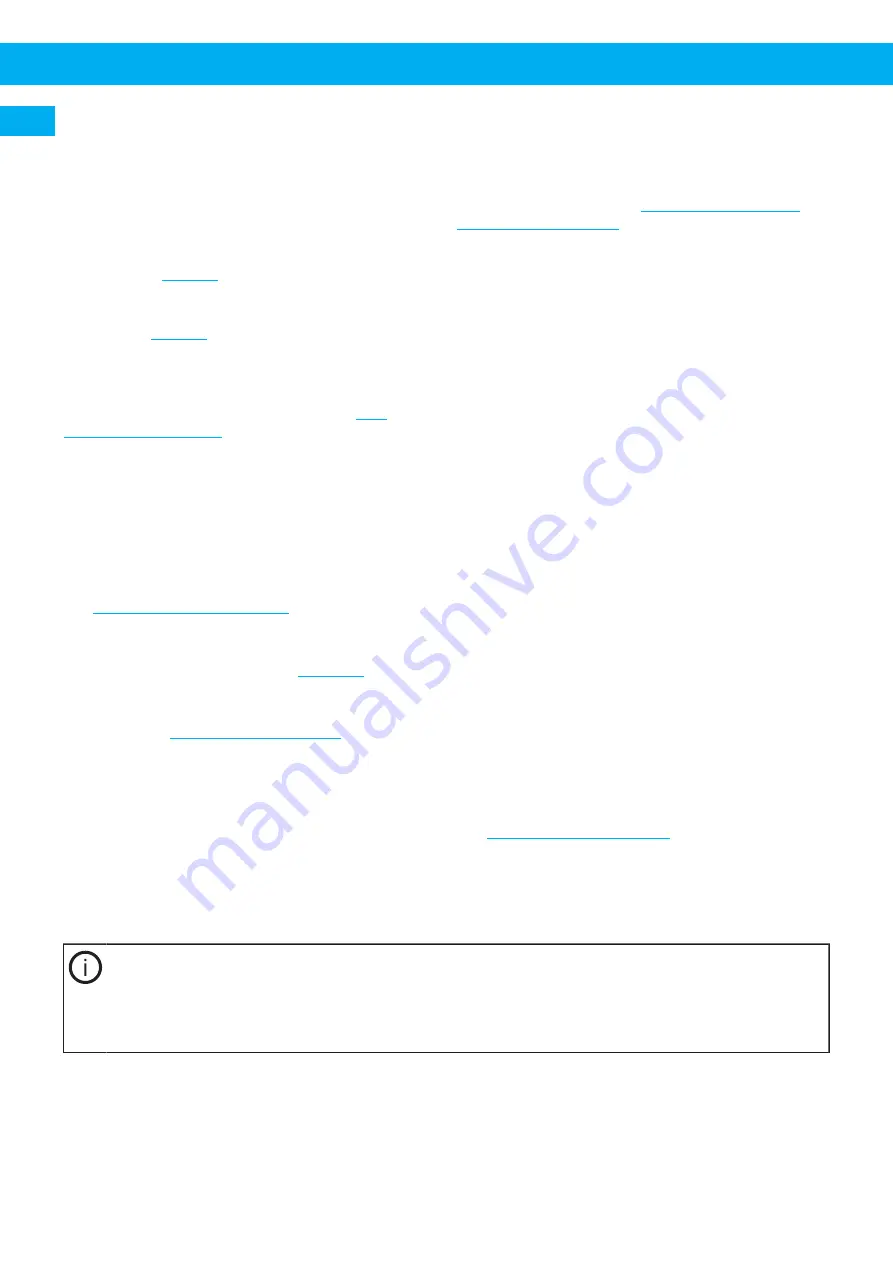

Page 16: ...FlexPAK A 4x B 19 Min 2 1m 83 20 1 0m 39 4 21 16...

Page 17: ...FlexPAK A B C 22 23 17...

Page 39: ...FlexPAK SUV Solenoid upper valve TVFD Twin valve feed out device EN 39...

Page 60: ...FlexPAK CS SUV Horn elektromagnetick ventil TVFD Za zen pro vypou t n dvojit ho ventilu 60...

Page 81: ...FlexPAK SUV verste magnetventil TVFD Udgangsenhed for tvillingeventil DA 81...

Page 127: ...FlexPAK SUV V lvula superior solenoide TVFD Dispositivo de vaciado por doble v lvula ES 127...

Page 148: ...FlexPAK FI SUV Solenoidin yl venttiili TVFD Kaksoisventtiilipoistolaite 148...

Page 171: ...FlexPAK SUV lectrovanne sup rieure TVFD Dispositif de vidage double vanne FR 171...

Page 194: ...FlexPAK HU SUV Fels m gneses szelep TVFD Ikerszelepes kiadagol berendez s 194...

Page 216: ...FlexPAK IT SUV Elettrovalvola superiore TVFD Dispositivo di svuotamento a doppia valvola 216...

Page 239: ...FlexPAK SUV Bovenste magneetklep TVFD Uitvoer van apparaat voorzien van dubbele klep NL 239...

Page 260: ...FlexPAK NO SUV vre magnetventil TVFD Utmatingsenhet med to ventiler 260...

Page 283: ...FlexPAK SUV G rny zaw r elektromagnetyczny TVFD Dwuzaworowe urz dzenie odprowadzaj ce PL 283...

Page 312: ...FlexPAK RU FlexPAK FlexPAK DX 5 1 9 8 5 2 5 5 2 1 6 1 3 Running 8 8 6 312...

Page 323: ...FlexPAK 9 1 9 2 N e d e r m a n 2 3 11 9 3 1 2 3 4 12 5 13 6 7 14 8 RU 323...

Page 326: ...FlexPAK RU N e d e r m a n 11 1 FlexPAK 93 6 326...

Page 328: ...FlexPAK RU SUV TVFD 328...

Page 364: ...FlexPAK ZH 9 3 Nederman CE 9 1 9 2 Nederman 2 3 11 9 3 1 2 3 4 12 5 13 6 7 14 8 364...

Page 368: ...FlexPAK ZH SUV TVFD 368...

Page 369: ...www nederman com...