National Instruments Direct Injector Driver System Manual

© 2013 National Instruments. All rights reserved.

EPT Function Selection

There are four EPT function selections available in the

drop-down list. Each EPT function type is

optimized for a particular range of number of crank teeth. For example, the DI Driver System provides two encoder

pattern EPT functions, each optimized for different ranges of crank tooth counts. The suggested tooth count

ranges are shown below in Table 4.6.b for each pattern type selection. The EPT function extrapolation value,

which is the single-digit suffix of each EPT_Type selection, will affect the CAD resolution of the internally calculated

CurrentPosition. The worst case resolution is 0.500 CAD for very low encoder pattern tooth counts.

For example, if using a 4-stroke 36-1 pattern, then the suggested EPT function is the “EPT N-M 7”. The “7”

component of the selection refers to the number of bits of binary extrapolation of crank angle between each crank

tooth. In this case, CurrentPosition would increment by 2^7, or 128 CAT, between each crank tooth. The range of

CurrentPosition would be from 0 to MAX_CAT = 2*36*128 = 9216. This is the total number of angular positional

ticks that are tracked by the EPT over a complete 4-stroke engine cycle. Therefore CurrentPosition will track

from 0 to 9216 and roll over to 0 at the occurrence of tooth 0. This provides an angular resolution of 0.078 CAD/

CAT. The calculated CurrentPosition is maintained with a 16-bit integer and cannot exceed 65535. Therefore,

should not exceed a value that causes

to exceed 16-bit representation. The

value is displayed on the EPT tab.

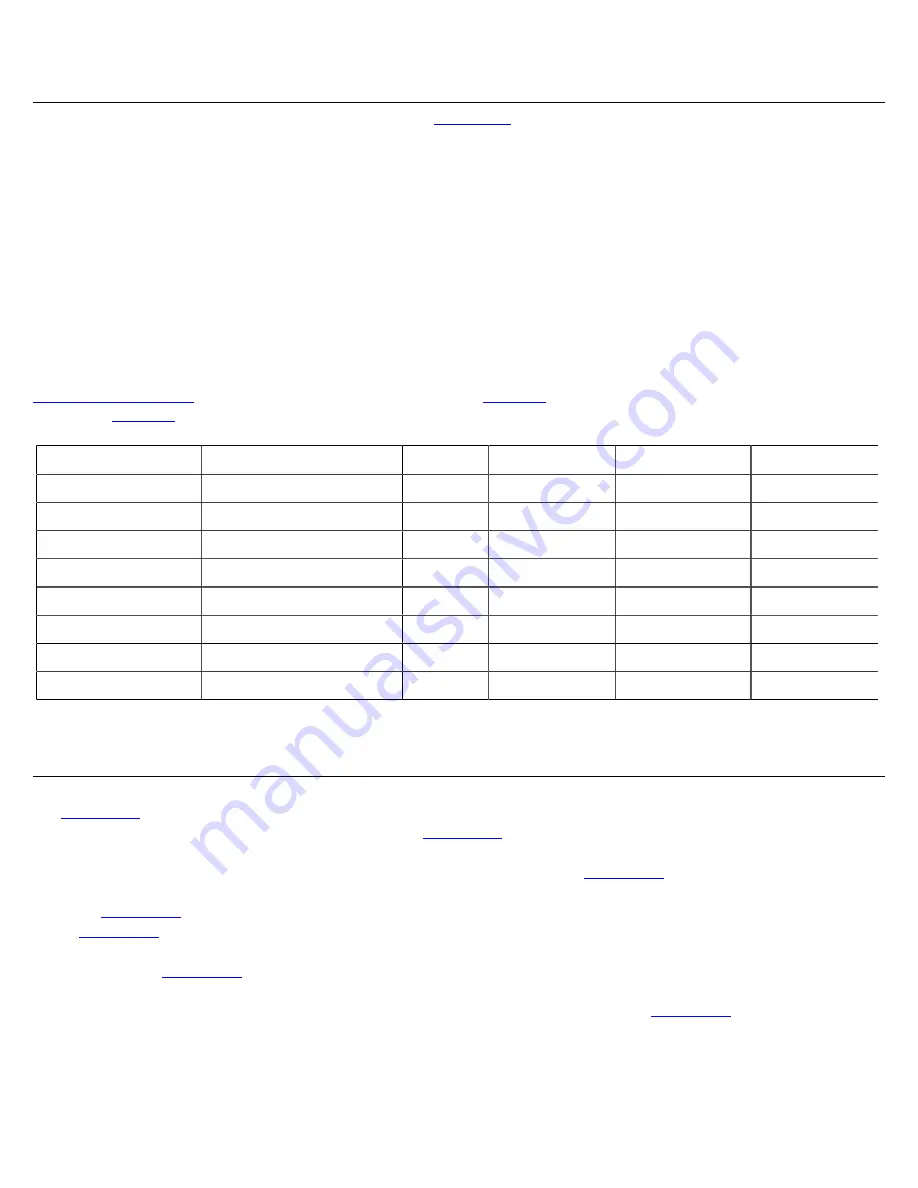

Pattern Type

NumberOfCrankTeeth

Stroke

Extrapolation

MaxCAT

CAD / CAT

EPT ENC 2 (max)

3600

4

2

28800

0.025

EPT ENC 2 (min)

180

4

2

1440

0.500

EPT ENC 4 (max)

720

4

4

23040

0.031

EPT ENC 4 (min)

45

4

4

1440

0.500

EPT N-M 7 (max)

120

4

7

30720

0.023

EPT N-M 7 (min)

12

4

7

3072

0.234

EPT N+1 9 (max)

24

4

9

24576

0.029

EPT N+1 9 (min)

4

4

9

4096

0.176

Table 4.6.b, EPT function Extrapolation Values and Suggestion Tooth Count Ranges

Loss of Sync

The EPT will lose sync under normal conditions if the crankshaft speed falls below the stall speed, as specified by

the

parameter of the EPT tab. Keep in mind that the EPT function uses a 24-bit, 40MHz timer to measure

the period between each physical tooth. Therefore, a

should be specified such that the tooth period timer

will not exceed 24-bit representation. This is a straight-forward calculation for encoder patterns. For example, if a

180-count encoder were used on the crankshaft, and it is desired to have a

tooth period timer for that speed (266666) must be checked so that it does not exceed a 24-bit value (2^24). It does

not, so a

of 50 RPM is acceptable. When EPT N-M 7 function is selected, extra attention must be given

to the

parameter. For example, if a 60-2 crank pattern is used, then there is a two-tooth gap, which

means that the timer period during the gap will be three times the period between the other evenly spaced teeth.

of 50 RPM correlates to an evenly spaced tooth period of 20 milliseconds. Therefore,

the period during the gap would be 60 milliseconds at 50 RPM. Sixty milliseconds correspond to a 40 MHz timer

value of 2400000, which can be represented by a 24-bit value. Therefore, a 50 RPM

this example.