MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

11

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

Cartridges are supplied packed under vacuum and must remain closed until

installed.

The cartridge must always be changed following periods of inactivity of more than

2 months while mounted on the compressor. Use only original spare parts

supplied by Nardi Compressori.

The original spare cartridges supplied by Nardi are sealed inside a vacuum pack

and inside a paper tube to protect them from impact. Pay attention to the expiry

date on the container.

CONSTANT PRESSURE VALVE:

This type of valve serves to keep the final filter under constant pressure.

This makes it possible to eliminate a greater volume of water, improving the

quality of the air and the duration of the cartridge.

When the compressor is switched on the valve remains closed until the entire

system reaches

about 150 bar

and then opens.

The valve is calibrated by NARDI COMPRESSORI - if further calibration is

required contact the assistance centre.

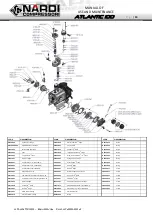

REPLACING THE 1

ST

STAGE VALVE:

Carefully study the figure for the correct positioning of the valve and check that the reed valve is turned with the

nut towards the suction filter. Replace the gaskets or O-rings if they show signs of deterioration.

REPLACING THE 2

ND

STAGE VALVE:

This valve must be cleaned or replaced as follows:

Disconnect the cooling pipes from the connectors.

Release the screw and completely detach the head from the cylinder.

Clamp the head in a vice.

Unscrew the valve cover.

Clean and remove all incrustations. If there are signs of wear change the complete valve.

Reposition all the components in the same order changing the sealing rings.

Test the operation of the valve by blowing compressed air in the direction of flow.

Check the O-ring seals. If damaged replace them.

Fix the head to the cylinder.

Fix the cooling pipes.

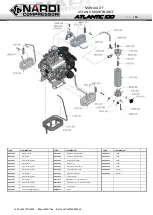

REPLACING THE 3

RD

TO 4

TH

STAGE VALVE:

This valve must be cleaned or replaced as follows:

Disconnect the cooling pipes from the connectors.

Release the screw and completely detach the heads from the cylinders.

Clean and remove all incrustations. If there are signs of wear change the complete valve.

Reposition all the components in the same order changing the sealing rings and take particular care that

when fixing the 4th stage head the final stage valve plate is not obstructed.

Check the O-ring seals. If damaged replace them.

Fix the head to the cylinder.

Fix the cooling pipes.

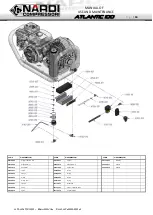

45

34

24

20

15

5

4

34

27

20

16

12

4

3

10

°C

/ 4

5°

F

15

°C

/ 5

9°

F

20

°C

/ 6

8°

F

25

°C

/ 7

7°

F

30

°C

/ 8

6°

F

35

°C

/ 9

5°

F

40

°C

/ 1

04

°F

Te

m

po

in

ore

/

H

ours

Temperatura °C / Temperature °F

Tempi cartuccia / Lifetime of Cartridge

ATLANTIC 100 (225 BAR)

Poco Umido/Slightly Humid

Molto Umido/Very Humid