MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

7

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

-

Close the filling hose valve (this automatically releases

the residual compressed air).

-

Disconnect from the cylinder.

-

Repeat the operations for the next cylinder.

Maintenance operations:

-

Follow the maintenance operations described on the

servicing sheets

-

Periodically replace the intake filter

-

Periodically replace the carbon and sieve filter cartridge

-

Periodically replace the filling hoses

-

Periodically check that the safety valves function

correctly at the maximum pressure

Switching on the compressor:

Electrical compressor without automatic control system:

This completely manual model requires a work cycle in which the machine must never operate on its own but must be constantly monitored and

controlled by a specialized operator.

The compressor is switched on simply by turning a switch and is switched off by the operator with the same switch.

The condensate that forms inside the two or three air/oil/water separation filters must be drained manually through three condensate release valves

every 8 to 10 minutes.

The maximum pressure is indicated on the overload valve by the escape of air.

WARNING: the maximum pressure valve is calibrated and sealed by Nardi Compressori. Any modification or tampering to this invalidates all

guarantees on the compressor.

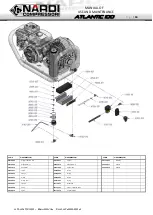

Engine driven compressor with manual start up:

Before starting up the internal combustion engine it is first necessary to release the pressure in the filler hoses and from the condensate separators.

After this the engine can be started up with the pull starter (manual start up).

The compressor has manual condensate release valves which must be opened every 8 to 10 minutes by the operator to drain the oil and water

residues that form inside the separation filters.

ATTACHING THE VALVE TO A CYLINDER:

WARNING: The valve is a very delicate component that enables connection of a cylinder to the compressor. It must be treated with

care without bumping against anything. It must not be cleaned with solvents or harmful products, and most importantly the pressure

indicated on it must never be exceeded.

Compressors are normally fitted with 200 bar (black) or 300 bar (red) valves.

Valves must be attached to cylinders as follows:

Check that the compressor is off and the cylinder valves are all closed.

Fit the valve to the cylinder.

Open the cylinder valve to a ¼ turn less than maximum.

Switch on the compressor.

Open the compressor valve and fill the cylinder.

At maximum pressure close the cylinder valve and the connection valve.

Release the residual air between the cylinder and connector and unscrew the valve.

If a pressure above 220 bar is required, this must be requested from Nardi Compressori, who will supply the necessary materials for

filling at greater pressures using different attachments and more highly calibrated safety valves.

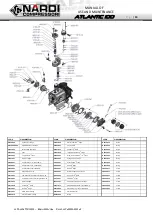

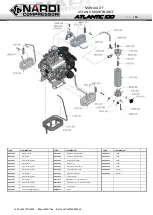

MAINTENANCE AND ASSISTANCE

MAINTENANCE OPERATIONS

:

In order for the machine to remain efficient over time it requires periodic attention. This will extend its working life and keep its

performance constant and efficient.

During operation the compressor requires routine maintenance that must be executed by technicians trained by Nardi Compressori.

If this operation is not conducted by our technicians, it is extremely important to follow the guidelines on the servicing sheet in all

details.

The following sheet sets out the routine maintenance operations to be followed on the basis of the number of hours of operation

completed by the compressor.

It is very important to record any maintenance operations conducted on the compressor in order to provide a history of replaced parts,

with the date of the day of maintenance, the number of operating hours of the compressor up to that moment, and the signature of the