MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

10

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

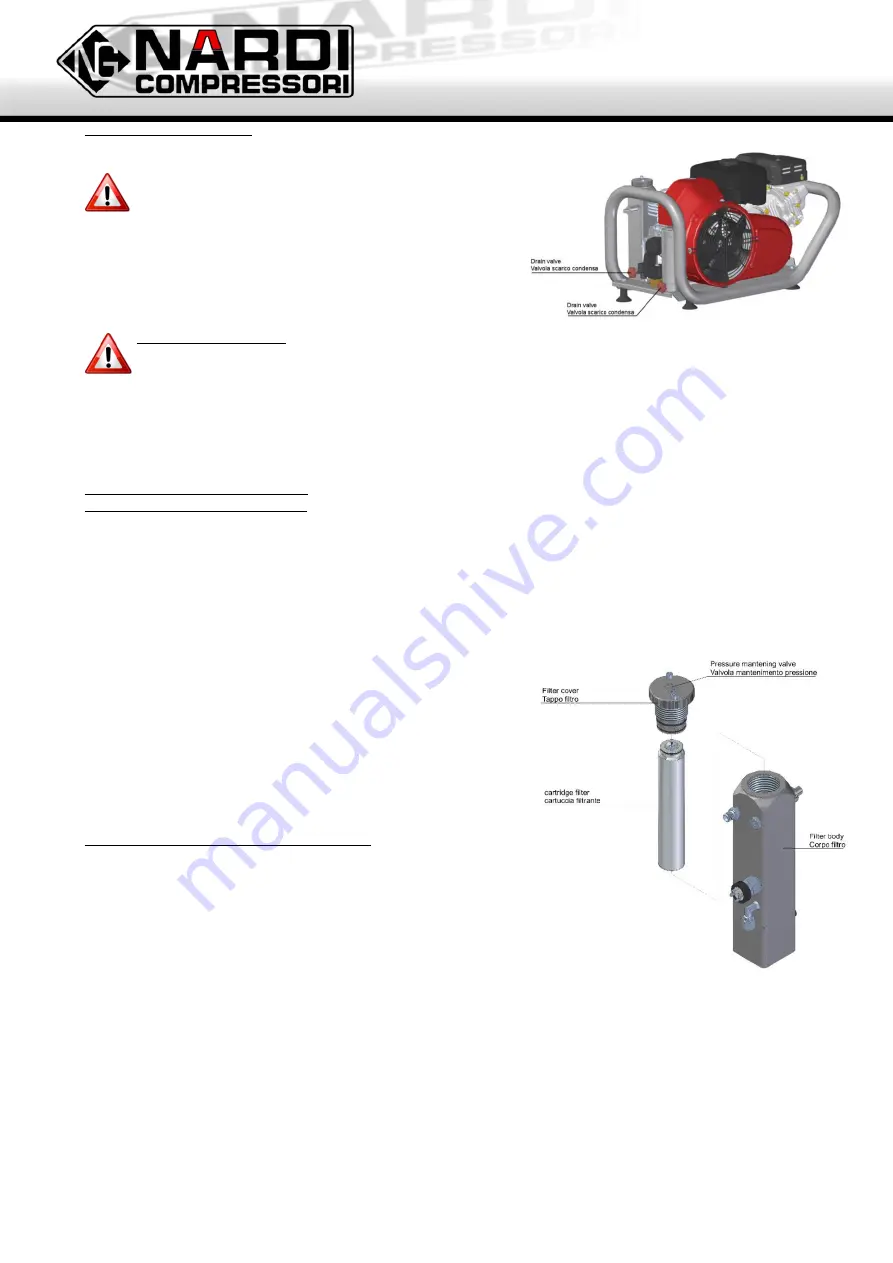

INTERMEDIATE SEPARATORS:

The intermediate separators serve to separate the condensate generated

from the air inside the compressor.

During the compression stage the air temperature is raised and between one

stage and the next it is cooled in a series of cooling coils.

This sudden change in temperature generates condensate that accumulates inside the

intermediate separators. It must be released by the operator at regular and constant

intervals, with no more than 10 minutes between release operations.

RELEASING CONDENSATE:

The condensate that forms inside the two air/oil/water separation filters must be manually drained through three condensate release

valves every 8 to 10 minutes.

If the compressor is equipped with automatic release then this operation occurs automatically. Care must be taken that this functions correctly, at

least during the first loading cycle or test it using the “TEST” button on the timer with the compressor running.

The release times can be adjusted on the timer as long as the OFF (PAUSE) time is not more than 15 minutes and the ON (RELEASE) time is not

less than 3 seconds.

If the compressor has a petrol engine or three phase electrical motor, the automatic release has a battery which should be disconnected when not

in use and it is important to check that it is charged so that the automatic condensate release functions.

CARBON FILTER FOR BREATHABLE AIR:

Carbon filters serve to remove any water and oil residues that pass through the intermediate separators.

The function of the filter is not mechanical but chemical, with materials that absorb the water and oil particles making the breathable and compliant

with standard DIN EN12021.

The filter has two safety features:

The first comprises a hole in the filter body which is closed when the cartridge is inserted. It functions by making it impossible for an operator to fill

cylinders in the absence of the cartridge.

The second safety feature activates if the top of the filter body accidentally becomes unscrewed, without decompressing the compressor. This

safety device provides an release path for the air inside.

The operating life of the filter components depends on the number of operating cycles.

The base and upper body are subject to dynamic loading caused by the pressurization

and depressurization of the filter. Nardi Compressori recommend inspection by

a specialized technician after every 500 hours of operation, and after 8000 cycles at

300 Bar or 21000 cycles at 225 Bar the entire filter should be replaced. Calculating

approximately 4 cycles per hour at 300 bar the filter could be changed after 2000 hours

of operation while at 225 Bar after about 5000 hours.

CARBON FILTER CARTRIDGE AND CARTRIDGE LIFE:

There are two types of cartridge: for electrical compressors and for engine driven compressors.

The cartridge replacement procedure is as follows:

-

Depressurize the entire system before starting any operations.

-

Unscrew the filter upper body handling it with care and avoiding any bumping.

-

Unscrew the cartridge.

-

Clean the inside of the filter with a clean cloth.

-

Screw in the new cartridge.

-

Check the condition of the filter O-ring - if damaged change with original spare O-ring.

-

Screw on the upper filter body by hand (do not use tools).

The life of the cartridge depends on various parameters including ambient humidity, temperature, compressor air capacity, cartridge size, etc.

New cartridges must be stored in a dry environment.