MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

2

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

GENERAL PRECAUTIONS:

Carefully read the following instructions before using the compressor

:

1. Carefully read all the instructions for the correct operation of the compressor.

2. Do not allow the compressor air output to be directed towards people or animals.

3. Do not operate the machine in humid unventilated environments.

4. Ensure that the compressor is located in a stable position.

5. The compressor's maximum pressure is clearly indicated on it.

6. When using the compressor, locate it in a cool environment away from sources of heat.

7. The compressor can reach high temperatures during operation.

8. Do not permit children to come into contact with the device even when it is switched off.

9. Do not intake/compress gasses other than air, or air with percentages of oxygen above 21%.

DESCRIPTION OF THE COMPRESSOR:

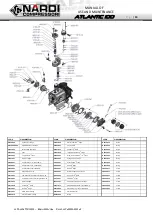

DESCRIPTION OF THE PUMP GROUP:

The ATLANTIC 100 pumping unit has a peak air pressure output of 330 bar (4700 psi).

The compressor has four stages driven by four pistons.

As can be seen in the following figure, the first stage in on one side, the second stage is on the opposite side to the first, and the third and fourth

stages are, at the top of the compressor body.

The pumping unit, containing as much as 350 ml of oil, is integrated with the filters, which are positioned between the cooling coils of the various

stages.

The unusual feature of the flywheel is its lightness. Thanks to the use of ultra-light alloys, the shaft does not need to balancing, automatically

eliminating vibration of the compressor while also limiting its overall weight.

Movement is transmitted to the pistons with rods through roller bearings. The latter can resist very high loads and ensure that these mechanisms

are very tough and precise.

The cylinders are in aluminium with a barrel in cast iron or steel, and internal lubrication bath. This feature makes the machine the most

technologically advanced product of its class on the market.

The resulting benefit is very rapid dispersion of heat, improving compressor performance and ensuring higher quality breathable air, thanks also to

a special guard cover that conveys and optimises the transit of the cooling air.

Furthermore, keeping the air at a lower temperature extends the life of the filter cartridges in the final filter, improving yield.

1. Compressor intake filter

2. 1

st

compression stage

3. 1

st

stage cooling coil

4. 2

nd

compression stage

5. 2

nd

stage cooling coil

6. 3

rd

compression stage

7. 3

rd

stage cooling coil

8. 4

th

compression stage

9. 4

th

stage cooling coil

10. Oil level indicator

11. Oil filling cap

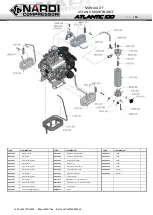

DESCRIPTION OF THE ATLANTIC 100 COMPRESSOR:

The ATLANTIC 100 structure comprises a compressor support base entirely in aluminium with an external tube that encloses the whole machine,

again in aluminium and protecting the compressor from impact, making the whole structure it tough, durable, corrosion resistant, while keeping the

overall weight very low.

The cooling fan cover grid is metal and highly resistant to accidental impact, improving machine safety.

The intermediate separator is located close to the fan, keeping it cool and so optimizing condensation, the final filter is located on the back of the

compressor group aligned with the cooling fan so that all the machine components are well cooled.

NARDI COMPRESSORI recommend releasing the condensate every 10 to 15 minutes. The two valves with red knobs on the separator

and compressor filter should be opened slowly, one at a time.

If the compressor is equipped with automatic condensate release, check that the system is functioning correctly.