MANUAL OF

USE AND MAINTENANCE

ATLANTIC 100

P g .

|

9

ATLANTIC 100 - Rev.00/16 Cod. AT200-002

Check the air quality with an aero-test

Calibration of automatic stop and safety valve

AFTER EVERY REPAIR

DATE

OPERATOR’S SIGNATURE

Check operation and seal of filling attachments

Clean intake filter

Pipe and cooling pipe connector seals

AFTER A LONG PERIOD OF INACTIVITY

DATE

OPERATOR’S SIGNATURE

Check operation and seal of filling attachments

Clean intake filter

Instruments, manometer zero

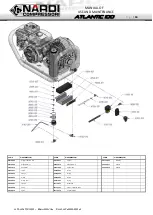

OIL:

The oil is an extremely important component for the duration of the compressor over time.

Nardi Compressori have carefully designed the machine so that it has an adequate capacity in its reservoir to ensure constant lubrication.

A screw cap is provided below the oil sump for easy oil changing.

The use of the specific Nardi Compressori oil is recommended. This special oil normally supplied with the compressor was designed and tested

specifically for this machine for producing normal breathable air, not for air mixtures (21% O²).

Oil characteristics:

-

Minimum deposits

-

Anti-carbonization effect

-

Excellent anti-corrosion properties

-

Physiological and toxicological suitability

OIL CHANGE:

The oil change procedure is as follows:

Ensure that sufficient oil is available for changing (L 0.350)

Switch on the compressor for 15 - 20 minutes to warm up the oil and

improve its fluidity.

Remove the oil fill cap and the oil vapour flange.

Remove the drain cap.

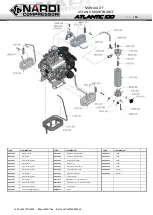

REPLACING THE INTAKE FILTER:

The filter serves to retain all the impurities present in the air.

It must be replaced at regular intervals as indicated in the maintenance table.

It must not be washed but instead blown clean with compressed air, or replaced.

The replacement procedure is as follows:

- Release the cover clips and extract the cartridge.

- Clean the inside of the casing and cover with a damp cloth.

- Insert the new cartridge/filter and close the cover.