11

© by N&W GLOBAL VENDING SpA

02-2007 266 00

Chapter 2

INSTALLATION

Installation and the following maintenance operations

should be carried out with the

machine switched on

and

therefore by qualified personnel only, who are trained in

the correct use of the machine and informed about the

specific risks of such situation.

To energize the system with the open door, simply insert

the special key into the door switch (see fig. 13).

The door can be closed only after removing the yellow key

from door switch.

The machine must be installed in a dry room with

temperature between 2" C and 32" C.

At installation the hydraulic circuits and the parts in

contact with foodstuff should be fully sanitised to

remove any bacteria which might have formed during

storage.

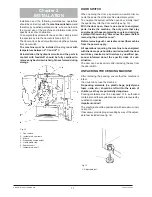

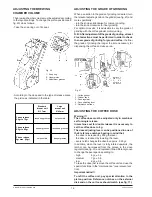

DOOR SWITCH

When opening the door a special micro-switch discon-

nects the power from the machine electrical system.

To energize the system with the open door, simply insert

the special key into the door switch (see fig. 13).

With the door open, there is no access to energised

parts. Inside the machine, the only parts that stay

energised are those protected by covers and carrying

a plate with the warning “Disconnect the power before

removing the protective cover”.

Before removing such covers disconnect the machine

from the power supply.

All operations requiring the machine to be energized

with the door open should be carried out with the door

switch key inserted, and therefore by qualified per-

sonnel informed about the specific risks of such

situation.

The door can be closed only after removing the key from

the door switch.

UNPACKING THE VENDING MACHINE

After removing the packing, ensure that the machine is

intact.

If in doubt do not use the machine.

No packing elements (i.e. plastic bags, polystyrene

foam, nails, etc.) should be left within the reach of

children, as they are potentially dangerous.

Packing materials must be disposed of in authorised

containers and the recyclable ones must be recovered by

qualified companies.

Important notice!!

The machine should be positioned with a maximum incli-

nation of 2".

If necessary provide proper levelling by way of the adjust-

able feet included (see fig. 14).

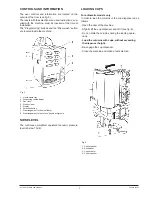

Fig. 13

1 - Door switch

2 - Instant prod. canisters

3 - Mixers

4 - Dispensing compartment

5 - Liquid waste tray

6 - Espresso unit

7 - Instant prod. shelf

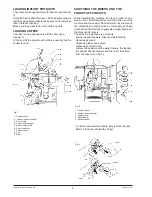

Fig. 14

1 - Adjustable foot

Summary of Contents for Colibri UL 120V

Page 2: ......

Page 4: ......

Page 44: ...N W GLOBAL VENDING S P A Sx39701...

Page 45: ...Colibr UL 120V Schema elettrico funzionale espresso semiautomatico...

Page 46: ...N W GLOBAL VENDING S P A Sx44700...

Page 47: ...Colibr UL 120V Schema elettrico funzionale espresso automatico...

Page 48: ...by N W GLOBAL VENDING SpA NOTE...

Page 49: ...by N W GLOBAL VENDING SpA NOTE...

Page 50: ...by N W GLOBAL VENDING SpA NOTE...

Page 52: ......