14

© by N&W GLOBAL VENDING SpA

02-2007 266 00

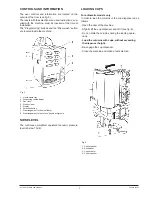

OPERATION

PRE-SELECTIONS

According to the layout settings, it is possible to have

different pre-selections; the available pre-selections for

each layout are indicated in the selection dose table

supplied with the machine.

Decaffeinated

This pre-selection is used for choosing whether the next

coffee based selection will be with decaffeinated type

coffee.

Syrups (with syrup kit only)

This pre-selection is used for choosing whether to add

syrup to the next selection.

Sugar (only for models with sugar dispenser)

This pre-selection is used, in unsweetened selections, for

adding sugar to the next selection

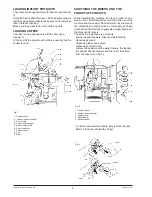

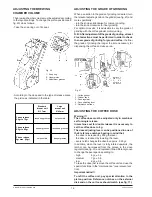

COFFEE DISPENSING CYCLE

After each time the machine is switched on, the coffee unit

is rotated completely before the normal cycle to ensure

that the device is in the correct start position.

According to the layout settings of the machine, the dis-

pensing cycle can be:

- With single grinding and single coffee release:

The grinder operates until filling the coffee doser chamber.

When the doser is full, the ground coffee dose is released

into the brewing chamber (1) positioned vertically (see fig.

17).

- With double grinding and double coffee release:

The grinder operates until filling the coffee doser chamber.

When the doser is full, the ground coffee dose is released

into the coffee brewer unit. The grinder starts for a second

grinding cycle and the dose is released again into the

brewing chamber (1) positioned vertically (see fig. 17).

After the release of ground coffee dose(s) is completed,

the ratiomotor handle engaged with the disk (2) located

outside of the assembly rotates by 180", making the brew

chamber swing and lowering the upper piston (3) (see fig.

18).

Due to the water pressure, the pre-brewing spring (5) sinks

and the lower piston (4) goes down 4 mm, thus forming a

water cushion which allows an even use of the coffee dose.

At the end of the dispensing cycle and during a pause of 3

seconds, the pre-brewing spring (5) will discharge the

water through the third way of the dispensing solenoid

valve, lightly pressing the used coffee dose.

By completing its rotation, the ratiomotor makes the swing-

ing lever (6) lift the pistons and the coffee dose.

At the same time, when the brewing chamber returns to its

vertical position, the scraper on the coffee hopper stops

the used coffee dose and drops it.

The lower piston now returns to the bottom dead centre.

Fig. 17

1 - Brewing chamber

2 - External disk

3 - Upper piston

4 - Lower piston

5 - Pre-brewing spring

6 - Swinging lever

7 - Markers

Fig. 18

1 - Brewing chamber

2 - External disk

3 - Upper piston

4 - Lower piston

5 - Pre-brewing spring

6 - Swinging lever

Summary of Contents for Colibri UL 120V

Page 2: ......

Page 4: ......

Page 44: ...N W GLOBAL VENDING S P A Sx39701...

Page 45: ...Colibr UL 120V Schema elettrico funzionale espresso semiautomatico...

Page 46: ...N W GLOBAL VENDING S P A Sx44700...

Page 47: ...Colibr UL 120V Schema elettrico funzionale espresso automatico...

Page 48: ...by N W GLOBAL VENDING SpA NOTE...

Page 49: ...by N W GLOBAL VENDING SpA NOTE...

Page 50: ...by N W GLOBAL VENDING SpA NOTE...

Page 52: ......