© by N&W GLOBAL VENDING SpA

26

02-2007 266 00

The integrity of the machine and compliance with the

standards of the relevant systems must be checked at

least once a year by qualified personnel.

Before starting any maintenance operations requiring

parts of the unit to be removed, the machine must

always be switched off.

The operations described below must be carried out

only by personnel who have the specific knowledge of

the machine functioning from a point of view of elec-

trical safety and health regulations.

INTRODUCTION

To ensure correct operation for a long period, the machine

must be subjected to regular maintenance.

The following sections contain the procedures and the

maintenance schedule, which are only a general indica-

tion, as they greatly depend on the operating conditions

(e.g. water hardness, environmental humidity and tem-

perature, type of product used, etc.).

The procedures described in this chapter are not exhaus-

tive of all maintenance operations to be carried out.

More complex operations (e.g. boiler descaling) should be

carried out by qualified technicians only having specific

knowledge of the machine.

To prevent oxidation or the action of chemical agents, the

stainless steel and varnished surfaces should be kept

clean by using mild detergents (solvents must not be

used).

Under no circumstances should water jets be used to

clean the machine.

ESPRESSO UNIT MAINTENANCE

Every 10,000 selections or every 6 months some mainte-

nance of the coffee unit must be carried out.

Maintenance is carried out as follows:

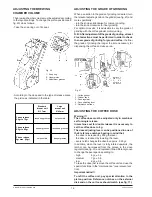

- remove the boiler Teflon hose connection from the upper

piston, paying attention not to lose the seal (see fig. 23);

- undo the knob securing the unit to the bracket;

- remove the coffee unit.

Removing the upper filter

- Take the snap ring out of its seat

- Remove the piston from the crosspiece

- Remove the filter and the piston seal

Chapter 3

MAINTENANCE

Removing the lower filter

- Open the two half-shells to access the internal brewing

chamber

- Extract the brewing chamber and remove the lower piston

snap ring.

- Take the piston out of brewing chamber and remove the

filter.

Soak all components removed from the unit in a solution of

boiling hot water and coffee machine detergent for approx.

20 minutes.

Thoroughly rinse and dry all parts, then reinstall them in the

reverse order of disassembly, taking particular care in:

- matching the two reference notches and inserting the

coffee unit;

- checking the efficiency of the seals, lubricating them with

food-safe grease.

Important notice!!!

During reassembly, check that the handle pin of the

ratiomotor is correctly engaged in its seat.

Fig. 26

1 - Ratiomotor handle pin

2 - Coffee funnel

3 - Brass ring nut

4 - Snap ring

5 - Brewer unit fastening knurled knob

6 - Lower piston fastening snap ring

7 - Reference notches

Summary of Contents for Colibri UL 120V

Page 2: ......

Page 4: ......

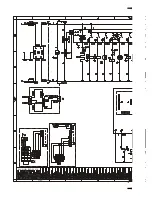

Page 44: ...N W GLOBAL VENDING S P A Sx39701...

Page 45: ...Colibr UL 120V Schema elettrico funzionale espresso semiautomatico...

Page 46: ...N W GLOBAL VENDING S P A Sx44700...

Page 47: ...Colibr UL 120V Schema elettrico funzionale espresso automatico...

Page 48: ...by N W GLOBAL VENDING SpA NOTE...

Page 49: ...by N W GLOBAL VENDING SpA NOTE...

Page 50: ...by N W GLOBAL VENDING SpA NOTE...

Page 52: ......