6. Anchor the incline on the desired end.

The motor goes in the

air

.

Bolt the bottom frame on and anchor to concrete

Set the desired height and drill two 3/8” holes to attach the

tall leg stand and anchor to concrete

7. Lower the off-fall bars until they are straight out

Bolt the back-side emergency stop pull cable bracket in

place – the e-stop is pre-wired

Bolt the L-bracket with the attached cable in an upright

position and run the cable to the switch

Tension the turnbuckle sot that the reset button has a good

solid click. If it is too tight it will not reset, if it is too loose it

will not reset. If you are unsure, take the cover plate off the

switch and align the pointer shown

With power on, test all e-stops to ensure they work

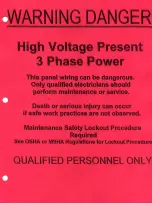

8. With the power off, wire the shaker and incline to the supplied

motor starters in the panel

Check direction of the incline, if it is running backwards

switch the red and white motor leads at the bottom of the

starter

9. Check rotation of each blade, the blade should spin in a

direction, so the teeth cut. –

NOTE

some blades rotate

clockwise, some counter clockwise. Start blades and observe

10. Once the rotation is identified, you are ready to check the draft

of each blade

Run a board through the conveyor and observe the board as

it cuts with a blade. The board should cut with the leading

edge and as the board passes the blade it should clear the

rear of the blade by 1/16”

If draft is needed or there is too much, adjust the pivot of the

blade to have the desired 1/16”. Consult with Monet

Desauw if you are unsure how to do this step.

11. Next you can check to make sure the board is traveling parallel

through the machine.

The moveable end has a timing sprocket on the rear of

the conveyor. This is pinned and set from the factory..

20

Summary of Contents for DESAUW FWA500

Page 1: ...MONET D ES AUW INCORPORATED 877 642 4900 ...

Page 2: ......

Page 3: ......

Page 4: ......

Page 12: ...8 Moveable End Electrical Cabinet Operator s Side Catcher s Side ...

Page 13: ...9 Blade 3 Guard ...

Page 16: ...12 ...

Page 17: ...13 ...

Page 18: ...14 ...

Page 19: ...15 ...

Page 31: ...MAINTENANCE SCHEDULE SERVICE SCHEDULE 27 ...

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ...Monet Desauw Inc FWA 500 Maintenance ...

Page 45: ...Angle Encoder Rack Adjustment ...

Page 47: ...Angle Encoder Adjustment ...

Page 48: ...Setting The Angle Digital Readout Scale Factor ...

Page 49: ...Angle Encoder D R O Adjustment ...

Page 51: ...Lower Conveyor Chain Adjustment Video ...

Page 52: ...Upper Hold Down Chain Tension ...

Page 54: ...Lower Feed Conveyor Timing ...

Page 56: ...Carriage Chain Adjustment ...

Page 58: ...Adjust Guide Bearings Video ...

Page 60: ...Center Line Adjustment Video ...

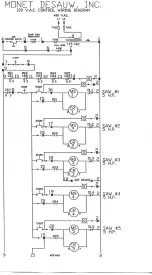

Page 62: ...Electrical Cabinet Components Variable Speed Frequency Drive ...

Page 63: ...Electrical Cabinet Components Control Relays ...

Page 64: ...Electrical Cabinet Components Transformer for 110 ...

Page 65: ...Electrical Cabinet Components Fuses and Fuse Blocks ...

Page 66: ...Electrical Cabinet Components Motor Starters ...

Page 67: ...Electrical Cabinet Components Lock Out Tag Out Disconnect ...

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......