10

9

30

*1

32

32

33

34

B

30

30

35

A

Pa

11

8

27

19

16

20

18

17

21

37

3

7

13

29

36

32

34 32

4

25

5

23

6

7

24

15 14

7

12

26

3

10

29

9

30

32

32

34

34

32

B

31

A

31

32

33

Pa

11

4

25

8

27

7

19

5

15

13

16

23

20

14

6

7

24

18

17

*1

7

30

22

12

26

39

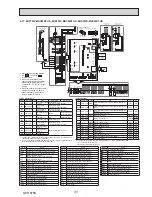

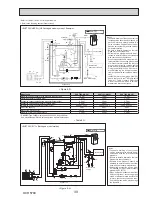

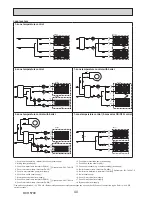

<EHPT20X-MHCW> (UK Packaged model system) <Example>

Notes:

• To enable draining of the cylinder unit an

isolating valve should be positioned on

both the inlet and outlet pipework. No

valve should be fitted between the ex

-

pansion valve (item 35) and the cylinder

unit (safety matter).

• Be sure to install a strainer on the inlet

pipework to the cylinder unit.

• Suitable drain pipework should be at

-

tached to all relief valves in accordance

with your country’s regulations.

• When using components made from dif

-

ferent metals or connecting pipes made

of different metals insulate the joints to

prevent any corrosive reaction taking

place which may damage any pipework.

• Filling loop’s flexible hose must be re

-

moved following the filling procedure.

Item provided with unit as loose acces

-

sory.

• Install the inlet control group (item 35)

above the level of the T&P relief valve

(item 21). This will ensure DHW tank

will not require drain-down to service/

maintain the inlet control group.

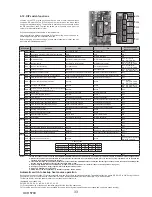

Model name

EHPT20X-MHCW

EHST20C-MHCW

EHST20D-MHCW

Maximum supply pressure to the pressure reducing valve

16 bar

16 bar

16 bar

Operating pressure (Potable side)

3.5 bar

3.5 bar

3.5 bar

Expansion vessel charge setting pressure (Potable side)

3.5 bar

3.5 bar

3.5 bar

Expansion valve setting pressure (Potable side)

6.0 bar

6.0 bar

6.0 bar

Immersion heater specification (Potable side) *

3000 W, 230 V

3000 W, 230 V

3000 W, 230 V

DHW tank capacity

200 L

200 L

200 L

Mass of the unit when full

307 kg

320 kg

312 kg

Maximum primary working pressure

2.5 bar

2.5 bar

2.5 bar

* EN60335/Type 3000W single phase 230V 50Hz, length 460 mm.

Use only Mitsubishi Electric service parts as a direct replacement.

<Table 8-1>

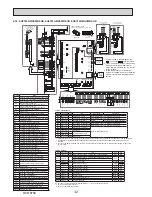

<EHPT20X-*M*C> (Packaged model system)

Notes:

• To enable draining of the cylinder

unit an isolating valve should be po

-

sitioned on both the inlet and outlet

pipework.

• Be sure to install a strainer on the inlet

pipework to the cylinder unit.

• Suitable drain pipework should be

attached to all relief valves in accord-

ance with your country’s regulations.

• A backflow prevention device must

be installed on the cold water supply

pipework (IEC 61770)

• When using components made from

different metals or connecting pipes

made of different metals insulate the

joints to prevent any corrosive reac

-

tion taking place which may damage

the pipework.)

<Figure 8-3>

<Figure 8-4>

Cylinder unit

Drain

Drain

Drain

Drain

Cold water

DHW

Local system

Main water supply

Flexible hose

(Temporary connection)

Cylinder unit

Drain

Drain

Cold water

DHW

Local system

Water

supply

Water pipe

Water pipe

•

Refer to <Table 4-1 and 4-2> for the part names.

*1 Refer to the following section [Local system].

OCH570C

Summary of Contents for EHPT20X-MHCW

Page 108: ......