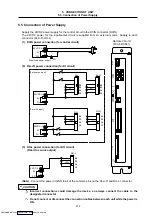

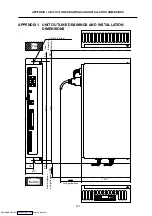

APPENDIX 3 CABLE MANUFACTURING DRAWINGS

I

-23

APPENDIX 3 CABLE MANUFACTURING DRAWING

As a rule, most F

/R

cables used with this product are not sold by Mitsubishi. Thus,

manufacture the required cables using the cable manufacturing drawings on the following pages as a

reference. Note that the cable-compatible connectors can be purchased from Mitsubishi.

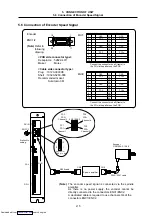

If crimp tools are not available when manufacturing the power supply cable (R200, R220) and

communication cable (R211), the cables can be manufactured by soldering a wire and connector as

shown in the following procedure.

1. Carry out preparatory soldering onto the wire.

(Peel 3.5mm of the sheath.)

Soldering iron

Wire

Solder

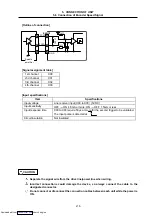

3. Lightly press down one side of the wire barrel

using radio pliers.

Wire barrel

This is a barrier to prevent

incorrect insertion. Do not bend.

Radio pliers

5. Firmly press down the sheath retainer in the

same manner as the wire barrel.

Sheath retainer

7. Lastly, insert the soldered contact with wire

into the housing.

Pay attention to the insertion direction.

2. Insert the wire into the contact. Hold

the sheath retainer.

Contact

4. Firmly press down the other side of the

wire barrel.

(Press firmly enough that the wire will

not come out when pulled lightly.)

6. Apply the soldering iron, and melt the

preparatory solder inside.

Better results will be achieved if an

additional, small amount of solder is

applied.

Soldering iron

Contact section

Be careful that the solder does not

flow into the contact section.

Downloaded from