SCSI Interface

126

Installation

Attention

It’s very important to protect the printer controller board and any

associated circuit boards from electrostatic damage. Before performing

this procedure, review the antistatic caution on page 105. In addition,

always handle circuit boards by the edges only.

1

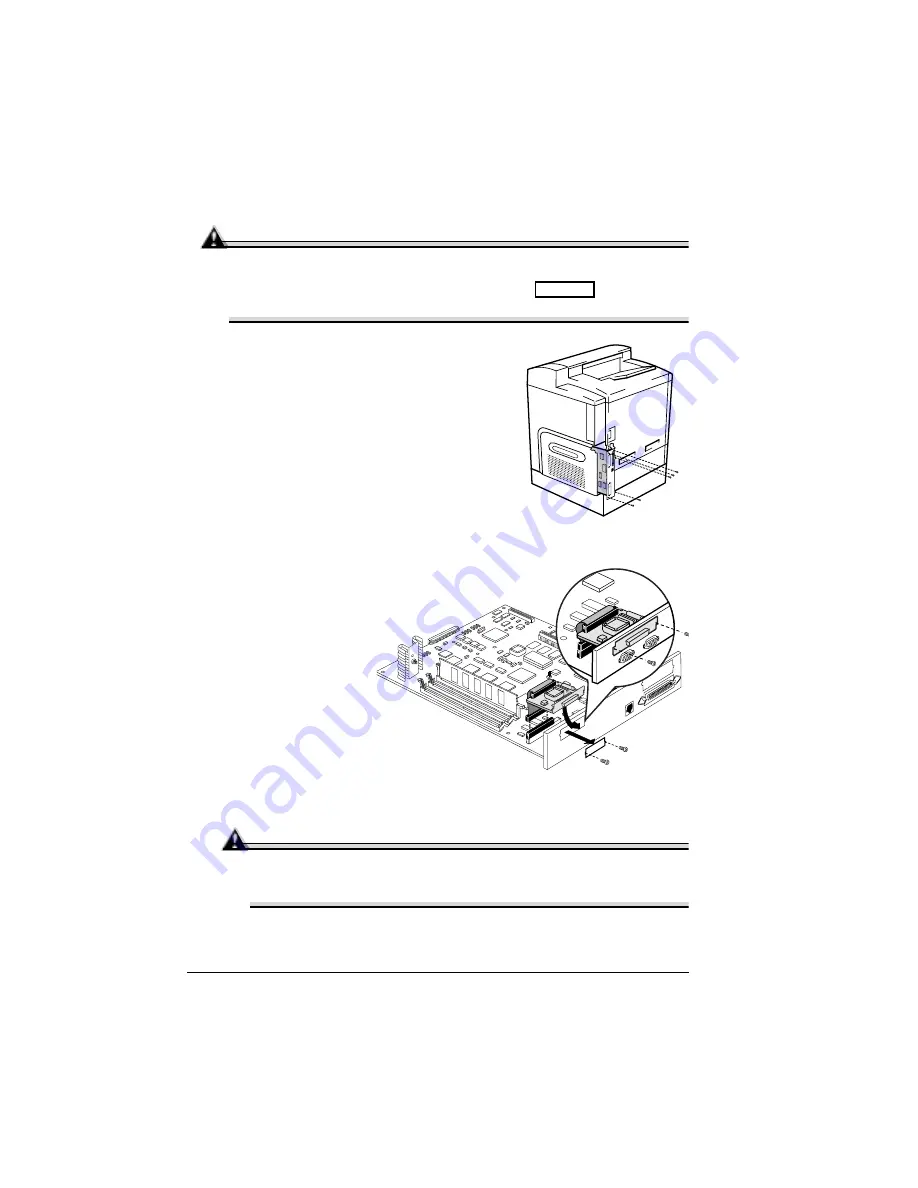

Turn off the printer, and then disconnect

the power cord and all interface cables

from the printer.

2

Loosen five screws and, using the tab on

the lower side of the panel, pull the

controller board from the printer.

3

Remove the two screws holding the metal

plate over the SCSI interface opening.

4

You can dispose of the metal plate and

screws according to local regulations.

5

Attach the SCSI

interface card to

the controller

board.

a

Position the

SCSI interface

card so that its

ribbon cable

connector

aligns with the

SCSI connec-

tor on the con-

troller board.

b

Gently press

the ribbon cable

connector down until it’s fully seated.

Attention

Make sure that the connectors on the ribbon cable and the controller

board are properly aligned. Damage to the controller board could

result if the pins are misaligned.

c

Insert the SCSI interface card connector into its opening in the

interface panel.

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII IIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIIII IIIIIIIII

................................................ ........................ ..........

................................................ ........................ ..........

................................................ ........................ ..........

................................................ ........................ ..........

..................

...................

..................

...................

Summary of Contents for MAGICOLOR 2210

Page 1: ...magicolor 2210 User s Guide 1800669 001B ...

Page 7: ...1 Replacing Consumables ...

Page 34: ......

Page 35: ...2 Using Media ...

Page 49: ...3 Maintaining the Printer ...

Page 53: ...4 Troubleshooting ...

Page 101: ...5 Installing Other Accessories ...

Page 140: ......

Page 141: ...6 Color Printing ...

Page 144: ......

Page 145: ...7 Repacking the Printer ...

Page 155: ...A Technical Specifications ...

Page 176: ......