9. Analyse the fill level values determined during setup mode. If the displayed values do not match the

ones of the reference measurement, the zero point will need to be adjusted. To do so, calculate the

difference between the fill level determined by the BLE Gauge sensor module and the reference

measurement and enter the difference in the input field for the "Trimming" parameter (see

"Measurement channels" on page 83). As the "Trimming" parameter is added to the measurement

value of the BLE Gauge sensor module, a negative prefix must be set for the "Trimming" parameter if

the determined fill level value is greater than the reference measurement (see "Additional explanation

on the zero point adjustment and installation height of the pressure sensor" on page 84).

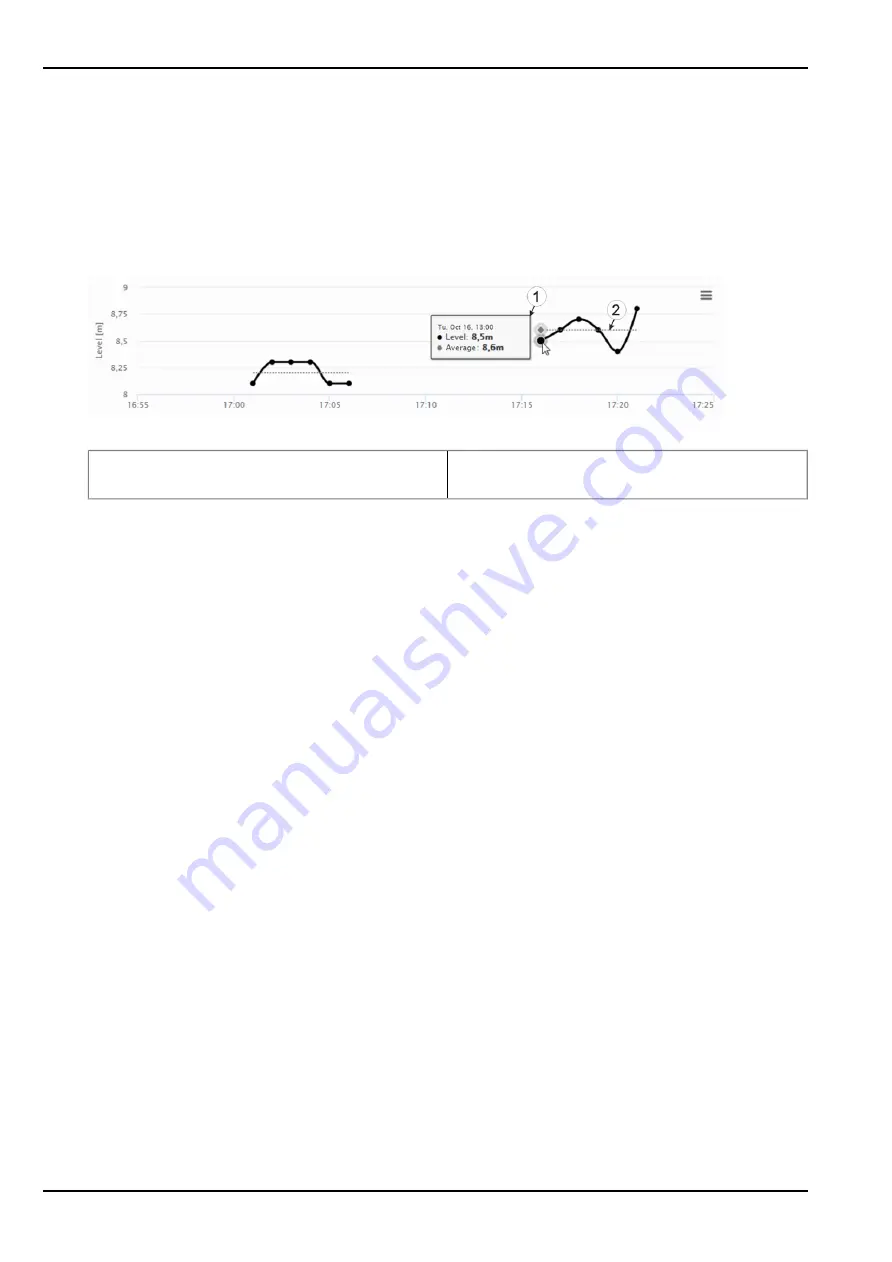

Display of the fill level determined during setup mode.

1

Tool tip that specifies the fill level at a certain

time and indicates the average value

2

Average of the data generated during setup

mode.

10. Activate setup mode again if zero point adjustment was required. During the initial connection

established during setup mode, the changed configuration, i.e. the new "Trimming" value, is first

transmitted to the myDatalogGauge 3G and then to the BLE Gauge sensor module.

11. Wait until setup mode is terminated and then compare the determined fill level values with the

reference measurement again. If the values are still not the same, complete the zero point adjustment

again.

Note:

The current value of the "Trimming" configuration parameter must now be taken into

consideration when calculating the difference between the determined fill level and the

reference measurement.

8.2.4.2 Zero point adjustment with the help of the Bluetooth connection (BLE)

Note:

As the minimum record interval is 1 min., this process is only suitable if the fill level is as

consistent as possible during the zero point adjustment.

1. Place the pressure sensor and the BLE Gauge in the final installation position (see "Suspended

installation of the BLE Gauge " on page 52).

2. Activate the required measurement channel in the "Measurement channels" configuration section by

selecting the mode and specifying the serial number of the BLE Gauge (see "Measurement channels"

on page 83).

Note:

If you have purchased the myDatalogGauge 3G as a set (data logger including up to 2 BLE Gauge

sensor modules), the serial numbers of the BLE Gauge are already saved in the memory of the data

logger. In this case, it suffices to select "Automatic" mode. The saved serial number is displayed in the

input field for the serial number, although it cannot be changed.

3. Enter the installation height of the pressure sensor in the input field for the "Sensor Offset" parameter

(see "Measurement channels" on page 83).

4. Ensure that the "Trimming" parameter is set to 0 (see "Measurement channels" on page 83).

58

Rev. 01

Summary of Contents for myDatalogGauge 3G

Page 2: ......

Page 10: ...2 2 BLE Gauge 10 Rev 01 ...

Page 11: ...Chapter 2 Declaration of conformity Rev 01 11 ...

Page 12: ......

Page 13: ...Chapter 3 Ex certification Chapter 3 Ex certification 3 1 BLE 3G Gateway ATEX Rev 01 13 ...

Page 14: ...14 Rev 01 ...

Page 15: ...Chapter 3 Ex certification Rev 01 15 ...

Page 16: ...16 Rev 01 ...

Page 17: ...Chapter 3 Ex certification 3 2 BLE Gauge Rev 01 17 ...

Page 18: ...18 Rev 01 ...

Page 19: ...Chapter 3 Ex certification Rev 01 19 ...

Page 20: ...20 Rev 01 ...

Page 134: ......

Page 140: ......

Page 152: ......

Page 154: ......