Page 29

Operation

surfaceCONTROL 3D SC2500 / SC2510

6.5.6

Surface Roughness and Texture

Surface roughnesses of the order of 5 µm and more as well as textures on the surface result in increased “surface

noise”. In addition, direct reflections of the projected light can also occur on grinding marks or small scratches on the

surface. This can result in inaccurate measured values. Remedy can possibly be provided by adjusting the exposure or

by other sensor settings, e.g. filter.

6.5.7

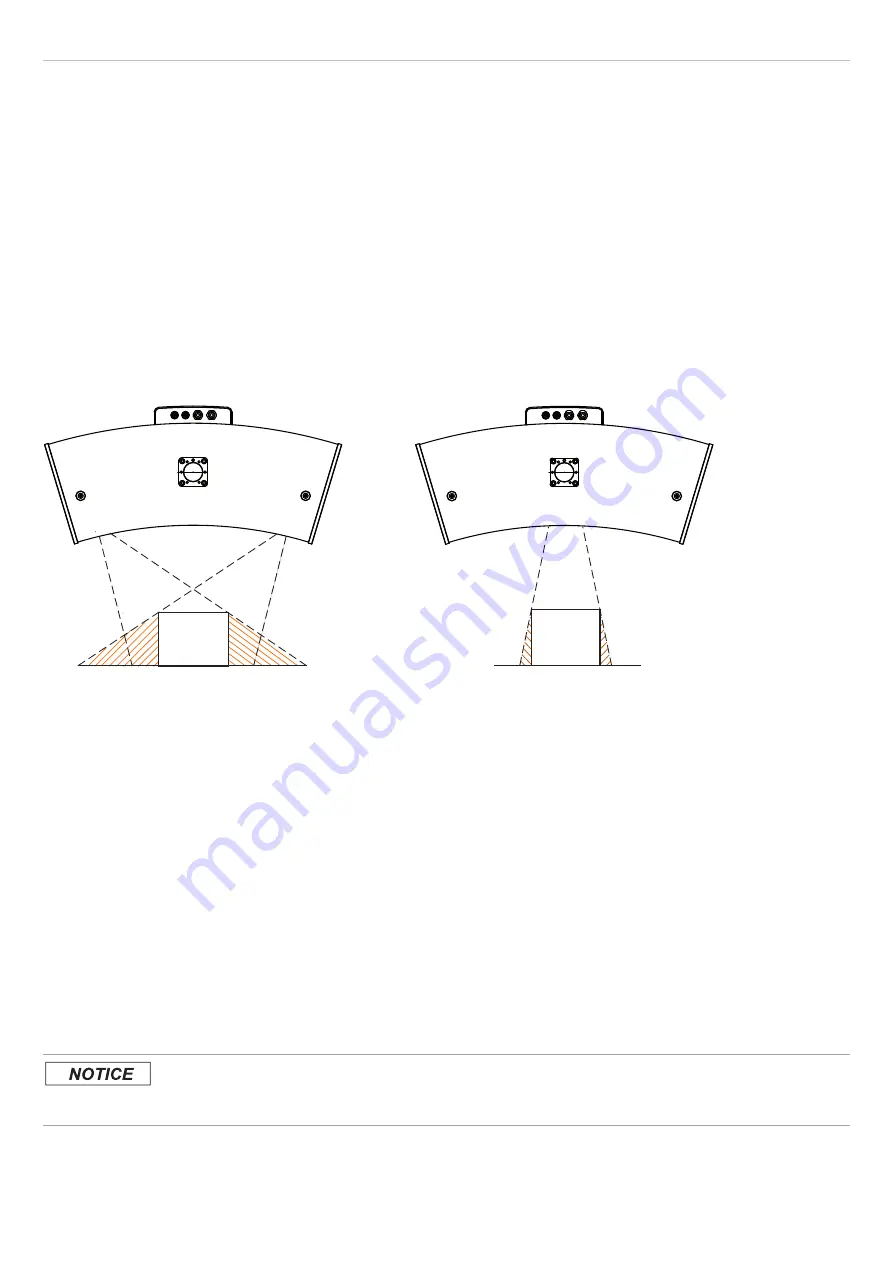

Shadowing Effects and Multiple Reflections

Shadowing effects and multiple reflections occur particularly frequently on strongly curved surfaces. Steep edges and

large differences in height lead to certain areas on the test object being underprojected. Furthermore, parts of the test

object cannot be detected completely by the cameras, which leads to a loss of measuring points on the surface. This

effect can be diminished by a change in orientation of the sensor to the surface.

Multiple reflections of the projected pattern from certain areas of the surface to other areas of the surface lead to over-

laps of the original pattern. This can result in inaccurate measured values. Remedy can possibly be provided by selec-

tively masking the projected pattern and not illuminating the undesirably reflecting areas. The procedure for masking

certain areas is described in the instruction manual of the surfaceCONTROL Defmap3D software. However, if you want to

check these areas anyway, repeated data acquisition with modified masking is necessary.

Fig. 27 Receiver shadowing

Fig. 28 Projection shadowing

6.6

Cleaning

6.6.1

Housing

It is not recommended to clean the housing. But if cleaning needs to be carried out, this can be done using water with-

out additives and a soft cloth.

6.6.2

Protective glasses / Filter

The lenses of the cameras and the projector are protected as standard by protective glass filters screwed onto the lens-

es. We recommend cleaning the protective filters regularly.

Dry Cleaning

You can use an anti-static brush for lenses, or blow down the covers using dehumidified, clean, oil-free compressed air.

Wet Cleaning

Use a clean, soft, lint-free cloth or lens cleaning paper and pure alcohol (isopropyl alcohol) to clean the protective glass

pane.

Never use commercially available glass cleaner or other cleaning agents.

When cleaning the protective filters, make sure that you do not change the settings of the lenses and

do not exert any strong pressure on the cameras or the lenses.

> Recalibration is possibly required

Summary of Contents for surfaceCONTROL SC2500

Page 4: ...surfaceCONTROL 3D SC2500 SC2510...

Page 41: ......