Page

41

of

64

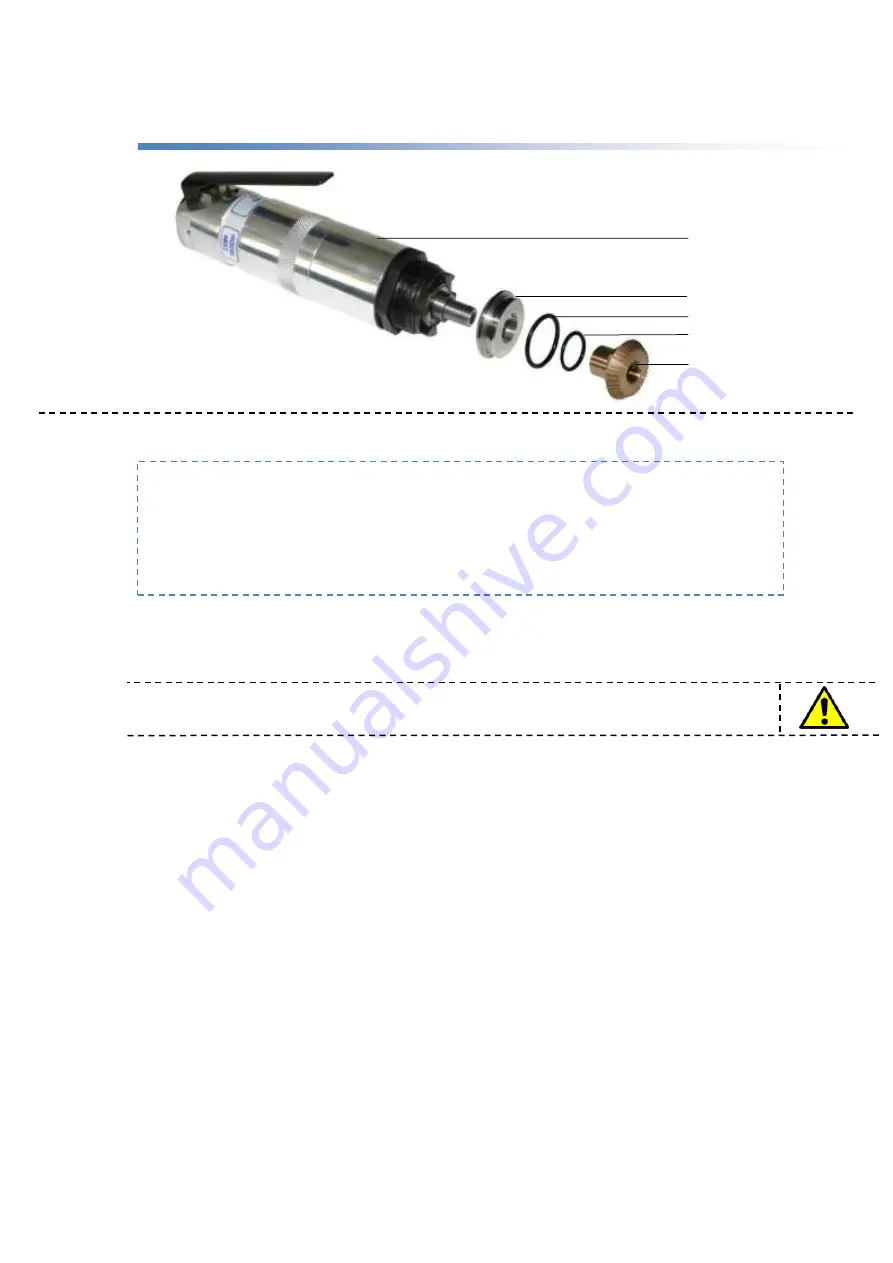

4.7 The Drive Motor

4.7.1 Dismantling the Drive Motor

Screw the Motor

(A)

out of the body (left hand thread) using a suitable spanner from the

Toolkit provided (part no. TKG73)

NOTE:

Never

clamp the motor directly in a vice.

Unscrew the Bevel Pinion

(E)

from the motor output shaft using a suitable spanner and

Allen key, and then separate the Seal Housing

(B)

from the Bevel Pinion

(E)

.

Discard both the inner and outer ‘O’ Rings

(C & D)

and inspect Bevel Pinion for wear.

4.7.2 Re-Assembling the Drive Motor

Fit new ‘O’ Rings

(C & D)

to both the inner and outer grooves of the Seal Housing

(B)

.

Lightly grease using Metallisation Grease (part no. 21173) and slide the Seal Housing

(B)

onto the boss of the Bevel Pinion

(E)

.

Screw the Bevel Pinion

(E)

and Seal Housing

(B)

onto the Motor Shaft, boss first and lock.

Screw the motor completely into the body (L/H thread) using the appropriate tool, taking

care to avoid damaging the seal ‘O’ Ring.

The Trigger Control (where fitted) should be located towards the front of the pistol (but

where it is comfortable to operate).

Run motor freely and check oil feed in the Air filtration Regulator.

DIAG 17

A

E

B

C

D

WHEN & WHY?

The Drive Motor Assembly should only be dismantled when it is absolutely necessary.

For example:

There is no wire drive.

Strip down of Gearbox indicates there is wear to the Bevel Gear.

There is evidence of air pressurising the Drive box i.e. there is greased pushed out around the Rollers.

Summary of Contents for MK 73

Page 1: ...Page 1 of 64 ssue 21 11 11 ...

Page 43: ...Page 43 of 64 SECTION 5 FAULT FINDING 5 1 Troubleshooting 5 1 2 Flowmeter Troubleshooting ...

Page 58: ...Page 58 of 64 SECTION 8 INFORMATION TABLES 8 1 Flowmeter Settings 8 2 Nozzle Selection Chart ...

Page 61: ...Page 61 of 64 Notes ...

Page 62: ...Page 62 of 64 ...

Page 63: ...Page 63 of 64 ...