Page

35

of

64

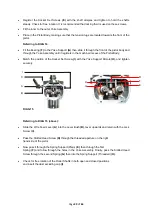

4.6.1 Dismantling the Wire Drive Assembly

Referring to DIAG 8

and Sub Assembly’s A-C:

Remove the Rear Wire Guide

(E2)

.

Remove the Gas Head, as in Section 4.4.

Unscrew the Bear Housing

(E1)

with a Peg Spanner / C Spanner and withdraw the

Wormshaft.

Separate the Bearing

(C4)

from the Bearing Housing

(C1)

, if necessary using an

appropriate tool.

Unscrew the Cap Retaining Screw

(C2)

from the end of the Wormshaft and remove the

Bearing Cap

(C3)

, Ball Bearing

(C4)

and Bevel Gear

(C5)

.

Examine all parts for wear.

Undo the 2 Roller Feed Nuts

(A1)

and remove the Wire Rollers

(A2)

.

Remove the Dust Excluders

(A3)

, Feed Roll Cover

(A4)

and Feed Roll Gasket

(A5)

.

Unscrew the Cover Screw

(B1)

found on the right hand side of the pistol.

Screw out the Slotted Head Screw

(B2)

, retain the Threaded Spring Support

(B4)

, Plain

Spring Support

(B3)

and Springs

(B5)

.

Slacken the Lock Screw

(E3)

and withdraw the Wire Feed Lever

(E4)

.

Remove the Socket Set Screw

(E9)

.

Remove the Spacer

(E7)

using one of the Gas Head Fixing Screws as an extractor.

Remove the Socket Set Screw

(E8)

.

Extract the Yoke Support

(E5)

and Bearing

(E6)

from the Pistol Body.

Taking the Yoke Assembly

(B6)

, unscrew the Socket Set Screws

(B7)

securing each

Roller Gear

(B8)

, and slide the Roller Shafts

(B9)

from the Yoke Assembly

(B6)

.

WHEN & WHY?

The Wire Drive Assembly should only be dismantled when it is absolutely necessary.

For example:

There is excessive play in Wire Rollers.

The Wire Rollers cannot be opened.

The Wire Feed Lever spins through 360°

Summary of Contents for MK 73

Page 1: ...Page 1 of 64 ssue 21 11 11 ...

Page 43: ...Page 43 of 64 SECTION 5 FAULT FINDING 5 1 Troubleshooting 5 1 2 Flowmeter Troubleshooting ...

Page 58: ...Page 58 of 64 SECTION 8 INFORMATION TABLES 8 1 Flowmeter Settings 8 2 Nozzle Selection Chart ...

Page 61: ...Page 61 of 64 Notes ...

Page 62: ...Page 62 of 64 ...

Page 63: ...Page 63 of 64 ...