IMPORTANT: Before using this equipment,

read all safety precautions and instructions.

Keep for future use.

DESCRIPTION

The gravity feed high volume low pressure

GFG gun is designed to apply a wide variety

of finishing materials. This gun was manu-

factured to provide maximum transfer effi-

ciency by

limiting air cap pressure to 10 psi

(complies with rules issued by SCAQMD

and other air quality authorities).

This gun will produce approximately 10 psi

cap pressure at 80 psi gun inlet pressure, as

measured at the gun inlet. An air cap test kit

(see

Accessories) should be used to insure

10 psi air cap pressure is not exceeded.

Note

This gun includes stainless steel

fluid passages, 300 series SS

needle and and 400 series SS fluid

tip. Guns may be used with chlo-

rinated solvent materials only if

the attached gravity cup is Acetal.

Do not use aluminum cups with

chlorinated solvent materials.

Note

The GFC gravity feed cups are only

included with the gun as part of

the gun-cup assembly. See

Accessories on page 6 for

more information.

Important:

This gun may be used with most

common coating and finishing materials. It

is designed for use with mildly corrosive

and non-abrasive materials. If used with

other high corrosive or abrasive materials,

it must be expected that frequent and thor-

ough cleaning will be required and the ne-

cessity for replacement of parts will be

increased.

INSTALLATION

For maximum transfer efficiency,

do not

use more pressure than is necessary to

atomize the material being applied.

1 .

Connect the gun to a clean, moisture

and oil free air supply using a hose size

of at least

5/16" I.D.

hose. Do not use

1/4" I.D. hose (25' x 1/4" hose at 18 CFM

has a pressure loss of 25 psi. 25' x 5/16"

hose at 18 CFM has a pressure loss of

8 psi).

Note

Depending on hose length, larger

I.D. hose may be required. Install an

HAV-501 air gauge at the gun handle

and air cap test kit over tip. When

SERVICE BULLETIN

SB-2-169-D

Replaces SB-2-169-C

Repair Kit KK-5025

GFG-517 GRAVITY FEED HIGH VOLUME LOW PRESSURE SPRAY GUN

gun is triggered on, adjust regulated

pressure to desired setting to pro-

vide a maximum of 10 psi at the air

cap.

Do not use more pressure than

is necessary to atomize the material

being applied.

Excess pressure will

create additional overspray and re-

duce transfer efficiency.

Note

If quick connects are required, use

only high flow quick connects (see

Accessories, page 6). Other types

will not flow enough air for proper

gun operation.

Note

If an air adjusting valve is used at the

gun inlet, use DeVilbiss Model HAV-

500 or HAV-501. Some competitive

adjusting valves have significant

pressure drop that can adversely

affect spray performance. Models

HAV-500 and HAV-501 have minimal

pressure drop, which is important for

HVLP spraying.

2 .

Attach the gravity feed cup to the

material inlet.

Note

Protective coating and rust inhibi-

tors have been used to keep the

gun in good condition prior to ship-

ment. Before using the gun, flush it

with solvents so that these materi-

als will be removed from fluid pas-

sages.

OPERATION

Mix, prepare and strain the material to be

sprayed according to the paint maufacturer's

instructions.

Strain material through a 60 or 90 mesh

screen.

1 .

Fill the gravity feed cup with the mate-

rial. Do not overfill. Make sure that the

cup lid vent hole is clear.

2 .

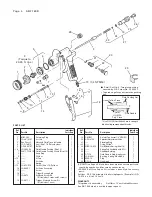

Open the spreader adjustment valve

(20) (Fan) by turning the valve stem

counterclockwise.

3 .

Close the fluid needle adjusting screw

(26) by turning clockwise.

4.

Turn on air supply and set gun inlet

pressure to lowest recommended pres-

sure for material being sprayed. Best

atomization will occur with 10 psig air

cap pressure. However, some materials

can be sprayed at lower pressures,

improving transfer efficiency.

5.

Spray a test area by turning fluid needle

adjusting screw (26) counterclockwise

until a full coat is obtained.

If the finish is too sandy and dry, the material

flow may be too low for the atomization air

pressure being used.

If the finish sags, there is too much material

flowing for the atomization air pressure be-

ing used.

Both of the above can be corrected by

increasing or decreasing the atomization air

pressure or the material flow. Pattern width

can be altered by turning spreader adjust-

ment valve (20), either clockwise to de-

crease the width or counterclockwise to

increase the width.

See Spray Gun Guide, SB-2-001 latest revi-

sion, for details concerning setup of spray

guns.

PREVENTIVE MAINTENANCE

To clean air cap and fluid tip, brush exterior

with a stiff bristle brush. If necessary to

clean cap holes, use a broom straw or

toothpick.

Never use a wire or hard instru-

ment.

This may scratch or burr holes caus-

ing a distorted spray pattern.

To clean fluid passages, remove excess

material from cup, then flush with a suitable

solvent. Wipe gun exterior with a solvent

dampened cloth. Never completely immerse

in solvent as this is detrimental to the lubri-

cants and packings.

Note

When replacing the fluid tip or fluid

needle, replace both at the same

time. Using worn parts can cause

fluid leakage. Tip and needle sets

are available. See Chart 2. Also,

replace the needle packing at this

time. Lightly lubricate the threads

of the fluid tip before reassem-

bling. Torque to 20-25 ft. lbs. Do

not overtighten the fluid tip.

To prevent damage to fluid tip (3)

or fluid needle (3), be sure to ei-

ther 1) pull the trigger and hold

while tightening or loosening the

fluid tip, or 2) remove fluid needle

adjusting screw (26) to relieve

spring

pressure against needle

collar.