Page

29

of

64

Check hose connection and hose condition and replace any connection or hose as

necessary.

As part of the routine maintenance, the system should also be leak tested at least every time

the system is assembled and once per week. (See Leak Test Procedure - Section 1.1.2).

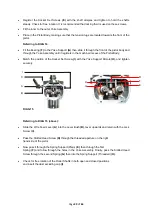

4.3 Disconnecting the Pistol

Follow the below procedure to disconnect the pistol:

Once the correct procedure for extinguishing the pistol has been carried out (Section

3.4), ensure that all supplies to the pistol are turned off and that the gas lines have

been emptied.

Disconnect all hoses at the pistol (remembering that the pistol gas union has a left

hand thread). Do not allow the hose ends to fall to the floor or be contaminated with

dust as this could damage the threads and introduce foreign matter into the valve

upon re-fitting.

Coil up the hoses and hang them in a safe place.

Leave the pistol valve open to avoid damaging the internal diaphragms

NOTE:

In order to prevent the ingress of any dirt, ensure that any further disassembly is

carried out in a clean environment.

Before proceeding to dismantle the pistol further, ensure that as a minimum the following

spares are available:

Part Number:

GAS-SSP

- MK61 / MK73 Standard Spares Pack for Gas Systems (See

Section 4.1

– Recommended Spares).

Visual representations of all recommended spare parts can be found in Section 7

– Illustrated

Parts List.

Summary of Contents for MK 73

Page 1: ...Page 1 of 64 ssue 21 11 11 ...

Page 43: ...Page 43 of 64 SECTION 5 FAULT FINDING 5 1 Troubleshooting 5 1 2 Flowmeter Troubleshooting ...

Page 58: ...Page 58 of 64 SECTION 8 INFORMATION TABLES 8 1 Flowmeter Settings 8 2 Nozzle Selection Chart ...

Page 61: ...Page 61 of 64 Notes ...

Page 62: ...Page 62 of 64 ...

Page 63: ...Page 63 of 64 ...