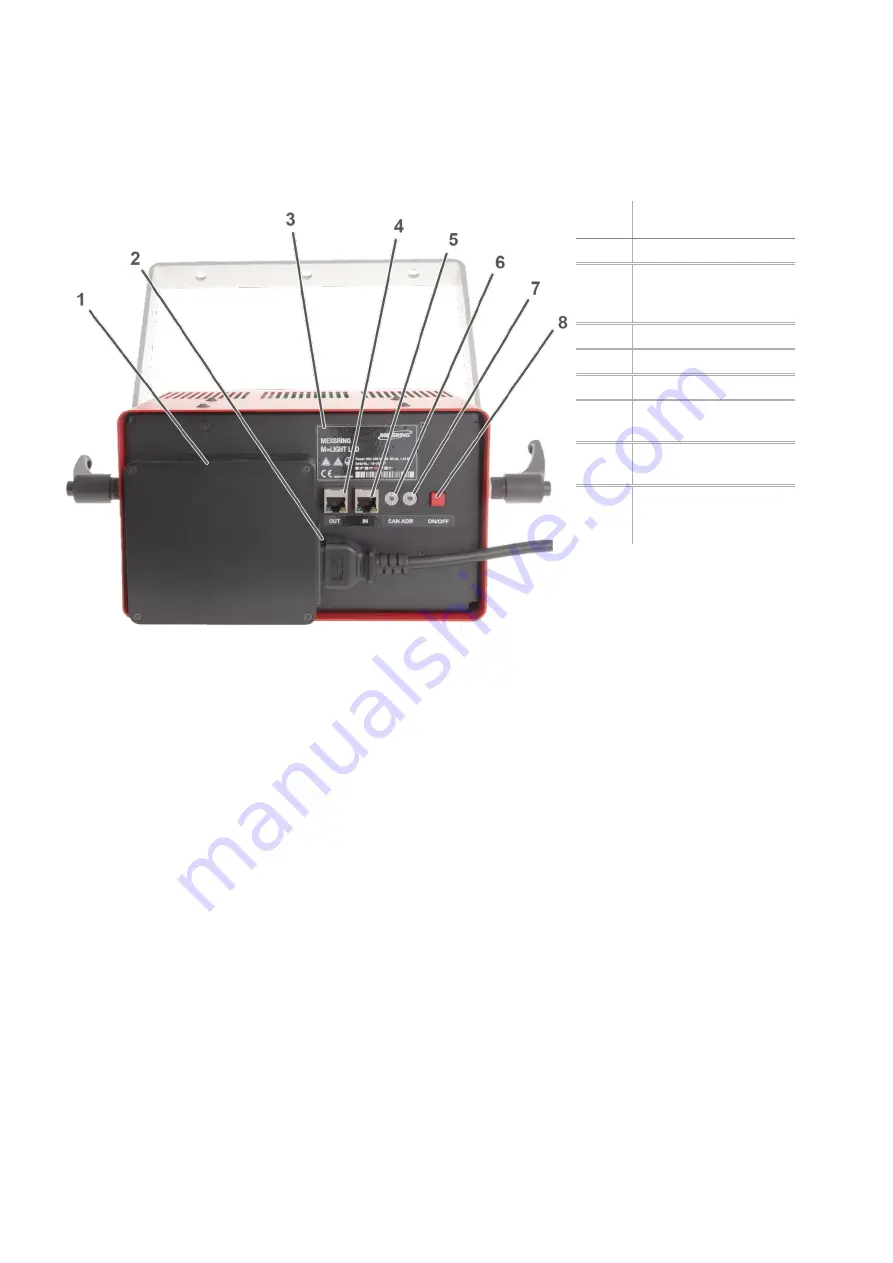

Rear Side of the Housing

Setup and Functioning

24

/

88

05.02.2019

8LE-D23_BA_E.docm

4.3

Rear Side of the Housing

Pos.: Description

1

EMC filter

2

Supply connection for

hot devices power

supply cord

3

Nameplate

4

CAN-bus Out

5

CAN-bus In

6

CAN-bus address

(MSB)

7

CAN-bus address

(LSB)

8

On / Off-switch,

manual operating

mode.

Figure 10: Connections and control elements on the rear side

4.3.1 Connecting / Disconnecting Voltage Supply

Connecting Voltage Supply

Establish line voltage via hot devices power supply cord (Figure 10, Pos. 2).

Note the connection rating (Section 7.2, Page 78).

Note the limits for voltage and frequencies (Section 7.2, Page 78).

Do NOT supply several M=LIGHT LEDs via multiple socket outlets.

Do NOT obstruct or block the line connection.

The line connection must be accessible at all times.

The M=LIGHT LED is now supplied with operating voltage.