www.maxcessintl.com

HEB250 Brake

MI 850A346 1 B

Page 14

Maintenance:

WARNING

– Danger of injury from crushing.

Maintenance and repair tasks on the brake must be performed only when the machine has been stopped

and has been secured from being turned on again.

Daily

– Keep the brake assembly free of dust and debris buildup during shift operation.

As Needed

– Keep the rotor free of excessive dust and debris buildup. Use a residue-free brake cleaner such

as turpentine, acetone, or

BioBrake

TM

to wipe down the rotor.

Fan Replacement

– Replace fan every three years or 30,000 hours of brake operation.

Brake Pads

– Calipers assemblies are designed to prevent brake pads from extending so far that the backing

plate rubs the rotor. New brake pads measure 15mm [0.591 in] in thickness. Since brake pads will stop

extending with 6mm [0.236 in] of overall thickness left (half of this is a metal backing plate) it is recommended

to replace brake pads prior to wearing the brake pads down to the 6mm [0.236 in] thickness. Note: brake pads

do not contain asbestos.

WARNING

– danger to eyes.

Wear eye protection when working with compressed air.

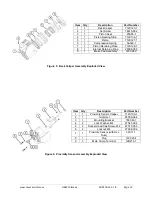

How to replace the brake pads:

A

For brakes WITHOUT a fan

shroud remove the fan finger

guard. For brakes WITH a fan

shroud remove the fan shroud.

B

Remove (4) bolts to dismount

each caliper mounting half.

C

Brake pads are clipped onto the

piston and are easily removed.

Dismount brake pads by prying

the brake pad away from the

piston until it has become

unclipped. To replace with a new

brake pad simply line up the tabs

of the brake pad with the tabs of

the caliper and press until the

pad has clipped in place.

D

Remount caliper mounting

halves using (4) each previously

removed bolts.