www.maxcessintl.com

HEB250 Brake

MI 850A346 1 B

Page 10

B

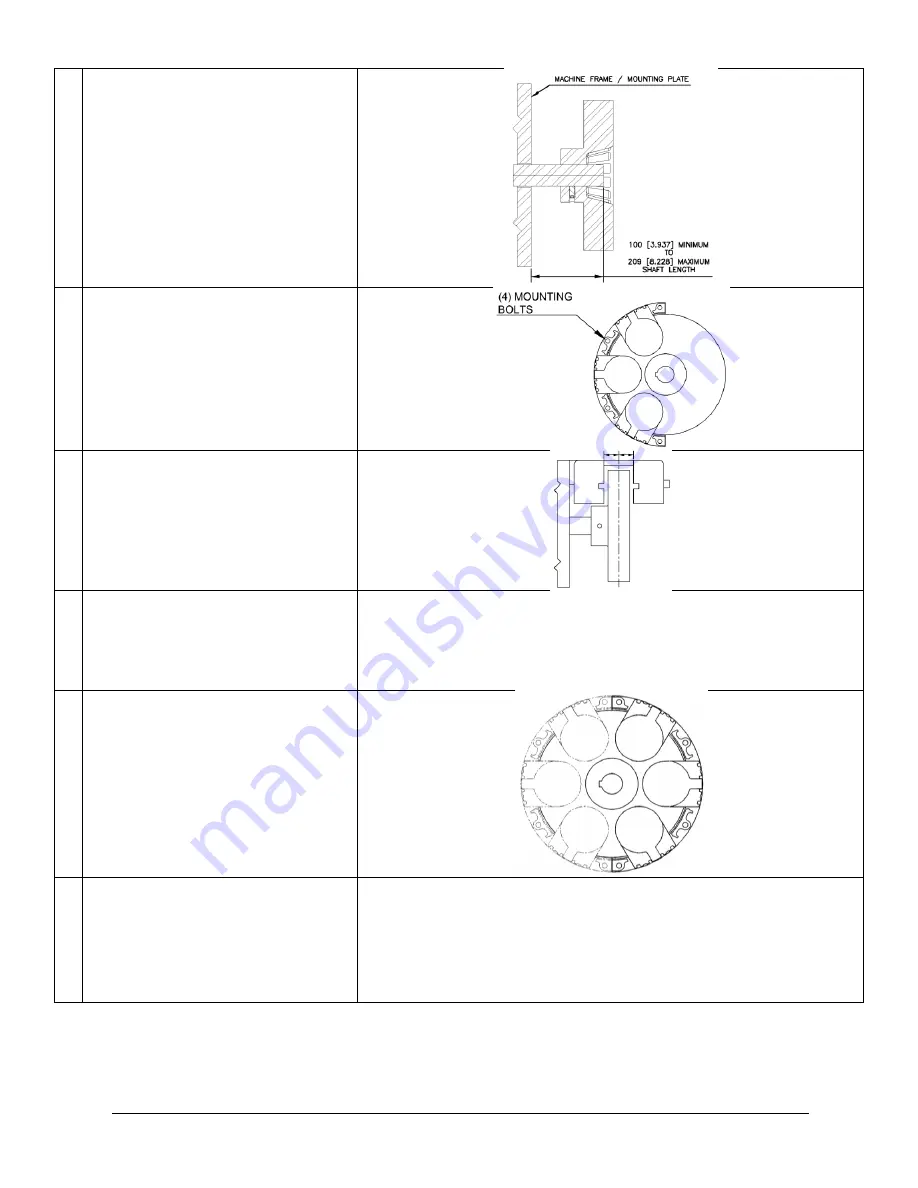

Mount the rotor on the shaft without

tightening the set screws.

C

Mount one of the caliper mounting

halves (halves are symmetrical, so it

does not matter which half) to the

machine frame using (4) ea M8x1.25

bolts. Tighten bolts to a torque of

40 Nm [29.5 lb-ft].

D

Center the rotor between the two

brake pads. Use feeler gauges or

equivalent to ensure equal distance

between the brake pad and rotor on

each side. Manually rotate the rotor to

verify the rotor does not touch any

brake pads during a full rotation.

E

Secure the rotor by tightening the two

set screws to the torque listed in the

Table 1. Install rotor set screws using

LOCTITE 266 high temperature, high

strength threadlocker or equivalent.

F

Mount the other caliper mounting half

to the machine frame using (4) ea

M8x1.25 bolts. Tighten bolts to a

torque of 40 Nm [29.5 lb-ft].

G

Install the airlines using 6 mm

[0.237 in] outside diameter tubing. Air

supply should be clean and dry, and

the pressure must not exceed

621 kPa [90 PSI].