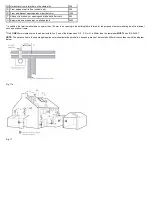

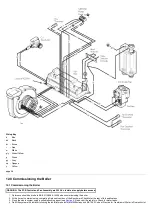

Fig. D

Flue Length - Worked Example Main 30 Heat

In

Above an additional 93° elbow and pair of 45°

elbows have been included in the 70Ø exhaust.

Also 3 straight extension pieces have been used.

To calculate total length:-

Length of 70Ø supplied in kit =

1 metre

3 x 1 metre Extensions =

3 metres

1 x 93° Elbow =

1 metre

2 x 45° Elbow =

1 metre (0.5 metres each)

Total 70Ø =

6 metres

After consulting the table in

that the concentric flue could be up to approximately 3.25

metres long.

page 28

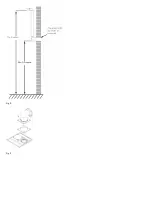

9.3 General Fitting Notes - P.D.K.

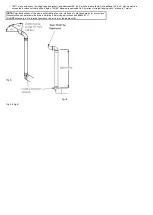

1. Cut a hole in the external wall which the horizontal concentric flue assembly will pass through.

2. When completed the terminal must be at least 2 metres above ground level (

3. Measure and cut to size the concentric assembly and any extensions that are being used.

4. Insert the concentric assembly through the hole from outside the building and mark the position of the flue trim securing holes.

5. Drill and plug the wall to accept the flue trim securing screws, and re-insert the concentric assembly through the wall.

6. Connect any extensions that are being used to the concentric assembly. Engage the extension or concentric assembly in the boiler flue elbow.

7. Fit the boiler flue elbow to the boiler top panel, ensuring the gasket is in place (

Ensure that the concentric assembly is horizontal and that the external air inlet is to the bottom.

Any extensions should fall back to the boiler.

8. Use suitable brackets to support the concentric assembly and any extensions, and make good inside and outside. Secure the flue trim to the wall.

9. The 70Ø exhaust can now be fitted to the spigot at the terminal end.

10. If it is necessary to shorten the 70Ø exhaust or any of the extensions, the excess material must be cut from the plain end of the pipe.

11. Determine the position of the 70Ø exhaust and mark on the wall a suitable position for the support bracket. Drill and plug the wall. If extensions are

being used, a support bracket is supplied in each kit.

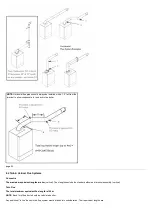

12. Engage the M6 threaded part of the mounting bolt in the boss on the support bracket. Using the bracket for leverage, screw the mounting bolt into the

plugged hole until the bracket is secure and level (

13. Slacken the two screws securing the retaining strap to the bracket, and pivot the strap aside to allow fitting the 70Ø exhaust.

14. Complete the installation of the 70Ø exhaust, securing in the brackets. Fit the 93° elbow and plume outlet. Ensure the plume outlet is at least 45° to

the wall and that the 'peak' is uppermost.

15. Continue with installation and commissioning of the boiler.

Summary of Contents for Main Heat 12

Page 8: ...Fig 3 Fig 4 Fig 5 Fig 6...

Page 38: ...Example 1 Example 2 Example 3...

Page 40: ...Fig E Fig F...

Page 51: ...Fig 31 Fig 32 Fig 33...

Page 55: ...Fig 35 Fig 36 page 39 12 2 Checking the Combustion 1 Follow the flow chart opposite...

Page 56: ......

Page 63: ...Fig 45 Fig 46...

Page 66: ......

Page 69: ...Fig 55 Fig 56 Fig 57 Fig 58...

Page 72: ...page 52...

Page 74: ...page 54...

Page 75: ...DRY FIRE...

Page 76: ...page 55 IGNITION LOCKOUT...

Page 77: ...page 56 OVERHEAT LOCKOUT...

Page 78: ...page 57 FAN LOCKOUT NOTE The fan is supplied with 325 Vdc...

Page 80: ...warranty This does not affect the customer s statutory rights page 62...

Page 82: ...page 63...