Chapter 10 Troubleshooting

10-1

Chapter 10 Troubleshooting

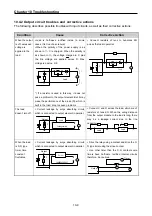

The following explains contents, diagnosis and corrective actions for various errors that can occur during system

operation.

10.1

Basic Procedures of Troubleshooting

System reliability not only depends on reliable equipment but also on short downtimes in the event of

faults.

The short discovery and corrective action is needed for speedy operation of the system. The following

shows the basic instructions for troubleshooting.

1) Visual checks

Check the following points.

•

Machine operating condition (in stop and operating status)

•

Power On/Off

- Status of I/O devices

- Condition of wiring (I/O wires, extension and communications cables)

- Display states of various indicators (such as POWER LED, RUN LED, ERR. LED and I/O

LED).

After checking them, connect peripheral devices and check the operation status of the PLC

option card and the program contents.

2) Trouble Check

Observe any change in the error conditions during the following.

•

Switch to the STOP position, and then turn the power on and off.

3) Narrow down the possible causes of the trouble where the fault lies, i.e.:

•

Inside or outside of the PLC?

•

I/O module or another module?

•

PLC option card program?

10.2 Troubleshooting

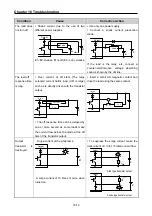

This section explains the procedure for determining the cause of troubles as well as the errors and

corrective actions

Errors

Is the ERR LED flicke

ring?

Are the RUN LED turn

ed OFF?

I/O module doesn’t op

erate properly

Program cannot be wri

tten

Flowchart used when the ERR LED is flickering.

Flowchart used when the RUN turned OFF.

Flowchart used when the output load of the output

module doesn’t turn on.

Flowchart used when a program can’t be written to

the PLC option card.