Appendix

ProtoMat M60

41

Strip and clean working depth limiters at regular intervals. To do this, first

switch the device off, then proceed as follows:

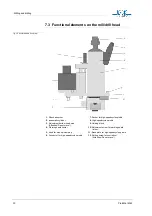

› Mark the insertion depth of the spindle (1).

› Remove connector from the spindle (2).

› Release Allen screw with which the high-speedcycle spindle is

clamped to the holding block (3).

› Spindle can now be pulled out towards the top (4). If necessary, turn

it slightly to the left or to the right.

› Remove the holding block.

› The working depth limiter (6) can now be removed toward the side

for cleaning .

› Clean both parts of the working depth limiter using the brush

provided.

Caution! Only lightly lubricate the thread of the working depth

limiter with graphite or Teflon!

› After cleaning the working depth limiter is refitted following the

procedure in reverse. The spindle is inserted into the holding block.

Observe the insertion mark!

› Check the correct insertion depth of the spindle before setting it into

operation. The distance between the drill tip and the machine plate

must be 0.5 mm when the head is in its lower position.

Caution! The machine plate can be damaged during drilling when

this distance is too small. At an insufficient distance the device can

no longer drill through the workpiece.

› At last tighten the screws again (3) and put the connector again on

the spindle.

Check the distance when mounting the high-speedcycle spindle