Milling and drilling

ProtoMat M60

35

For engraving, set the speed of movement as appropriate for the

engraving depth and the material. Use an LPKF universal milling cutter

or LPKF double chamfered cutter.

Danger! Use extractor when engraving, too!

The LPKF

ProtoMat

can be used for milling through 3 mm thick

aluminium front panels.

7.9 Milling layout films

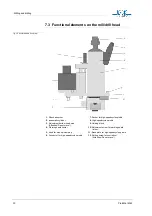

fig. 18: HF-Cutter

› Secure the film base (sheet of perspex or glass) on the machine

table with masking tape.

› Lay the film material on the base with the coated (matte) side facing

upwards.

› Now smooth the film material firmly and level on the film support until

the air has been completely expelled.

› Now stick down the film on all four sides with transparent adhesive

tape (which must not stretch) to form an air seal. There must not be

any air bubbles between the film and the base.

The milling depth can now be set at the film edge. It can be checked

by milling a frame around the film area (manual movement).

› The speed of movement should be reduced to about 15 mm/sec.

Note: The HF-cutter 0,25 mm is used for the milling of layout films.

› Switch on extractor, but only to half power, by extracting "secondary

air" on the suction nozzle or, if there is one, reducing the power on

the electronic extractor control.

The film milling program can now be started.

Film material comes in DIN A3 and A4 formats (special sizes available

upon request).

Note: The film coating is easily scratched and is water soluble, so

do not let it come into contact with water. The film can be recopied

with a coloring device upon request. For further notes see chapter