Milling and drilling

ProtoMat M60

29

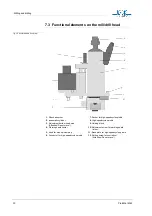

7.2 The mechanical working depth limiter

Danger! Keep your fingers away from the movement area of the

machine during operation!

When milling isolation channels in PCB materials, it is extremely

important to keep a constant milling depth. With the LPKF

ProtoMat

M60, this done by the mechanical working depth limiter.

This provides the following benefits:

• The depth limiter rides on the surface of the material. The

working depth limiter follows warped PCBs.

• The material is held down within certain limits by the working

depth limiter.

The head is lowered with a solenoid and raised with a spring.

fig. 9: The LPKF ProtoMat M60

working depth limiter

Milling depth is set by adjusting the knurled nut (2) on the working depth

limiter. When the wheel is turned clockwise, the milling depth is

increased, while it is reduced when turned counterclockwise. The milling

depth is altered by about 4 µm per step. Turning the knurled knob in

counter-clockwise direction is difficult when the head is lowered.

1

- Holding plate

4

- Suction nozzle

2

- Knurled nut used to set milling depth

5

- Tool fixture (collet for manual clamping)

3

- Holding block for working depth limiter

6

- Scanning ring in the working depth limiter