V

¨

In case of input voltage unbalance, install AC reactor. Power Factor capacitors and

generators may become overheated and damaged due to potential high frequency

noise transmitted from inverter.

¨

Use an insulation-rectified motor or take measures to suppress the micro surge voltage

when driving 400V class motor with inverter. A micro surge voltage attributable to

wiring constant is generated at motor terminals, and may deteriorate insulation and

damage motor.

¨

Before operating unit and prior to user programming, reset user parameters to default

settings.

¨

Inverter can easily be set to high-speed operations, Verify capability of motor or

machinery prior to operating unit.

¨

Stopping torque is not produced when using the DC-Break function. Install separate

equipment when stopping torque is needed.

(5) Fault prevention precautions

¨

Provide a safety backup such as an emergency brake which will prevent the machine

and equipment from hazardous conditions if the inverter fails.

(6) Maintenance, inspection and parts replacement

¨

Do not conduct a megger (insulation resistance) test on the control circuit of the

inverter.

¨

Refer to Chapter 8 for periodic inspection (parts replacement).

(7) Disposal

¨

Handle the inverter as an industrial waste when disposing of it.

(8) General instructions

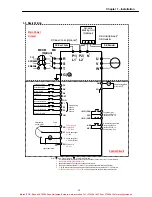

Many of the diagrams and drawings in this instruction manual show the inverter without a circuit

breaker, a cover or partially open. Never run the inverter like this. Always place the cover with

circuit breakers and follow this instruction manual when operating the inverter.

Morek IT OÜ, Rauna 24, 76506 Saue Harjumaa, Estonia. www.morek.eu Tel. +372 604 1423 Fax +372 604 1447 [email protected]