Page 8

To change jumper positions, gently pull the jumper off the

pins and place it on the desired set of pins. The following

section outlines the different jumper selections available

and conditions associated with each one. Refer to figure 4

for identification.

After the CFM for each application has been determined,

the jumper settings must be adjusted to reflect those

given in the tables on page 2. Using the tables, determine

which row of CFM volumes most closely matches the

desired CFM. Once a specific row has been chosen

(NORMAL or –), CFM volumes from other rows cannot

be used. Below are the descriptions of each of the

jumper selections.

Refer to table 4 for factory settings. Refer to the tables on

page 2 for the approximate air volume for each setting.

TABLE 4

MODEL

NUMBER

G25MV3-60

G25MV3-75

VSP2–1 FACTORY SETTINGS

HIGH

LOW

HEAT

1

4

1

2

4

3

ADJUST

NORM

NORM

G25MV5-100

2

4

1

2

4

3

NORM

NORM

G25MV5-120

The

ADJUST

pins allow the motor to run at normal speed

or approximately 10% lower than normal speed. The

tables on page 2 give two rows (NORMAL and –) with

their respective CFM volumes. The + adjustment setting

is not operable. Notice that the normal adjustment

setting for heat speed position #3 is 2030 CFM (960

L/s). After the adjustment setting has been determined,

chose the remaining speed jumper settings from

those offered in the table.

The TEST pin is available to bypass the VSP2–1 control

and run the motor at approximately 70% to test that the

motor is operational. This is beneficial primarily in

troubleshooting. G must be energized for motor to run.

For G25MV units, place the

jumper

across the second and third pins (position #2).

When W1 is energized, the

jumper selections are

activated. The

HEAT

jumper selections are activated

when W2 is energized.

NOTE–In Harmony II zoning applications, HEATING

BLOWER jumper must be in position #2.

The

HEAT

jumper is used to set the blower speed to

obtain the required CFM as outlined in HEAT SPEED

section of the tables on page 2.

The

HEAT

jumper selections are activated with a call for

second-stage heating (W2).

IMPORTANT

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper set-

ting change will not take place while the motor

is running.

The

HIGH

jumper is used to determine the CFM during

cooling speed. These jumper selections are activated

when G and DS terminals are energized.

The

LOW

jumper is used to determine CFM during low

speed cooling. These jumper selections are activated

when G is energized. The

LOW

jumper may also be used

for low speed heating. See the “HEAT” section for details.

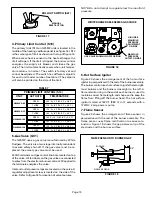

Fan “OFF” timings (time that the blower operates after

the heat demand has been satisfied) are determined by

the arrangement of a jumper on the VSP2–1 board. See

figure 6. To adjust fan “OFF” timings, gently disconnect

the jumper and reposition it across pins corresponding

with the new timing. Fan “OFF” time is factory set at

270 seconds. The control has a non–adjustable, factory

preset “on” fan timing (45 seconds).

FIGURE 6

FAN-OFF TIME ADJUSTMENT

270

210

150

90

To adjust fan–off timings:

Remove jumper from VSP2–1 and

select one of the other pin com-

binations to achieve the desired

time.

TIMING

JUMPER

TIMING PINS (seconds)

Leave jumper off to achieve

330 second fan–off timing.

Fan-off timing is factory

set at 270 seconds

NOTE—If fan “OFF” time is too low, residual heat in

heat exchanger may cause primary limit S10 to trip

resulting in frequent cycling of blower. If this occurs,

adjust blower to longer time setting.

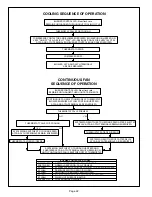

Table 5 outlines the operation of the variable speed

motor in relation to specific modes of operation. Some

information has been repeated from the previous section

to provide an example. Refer to each diagnostic LED or

jumper settings section for more information.