Page 14

Top

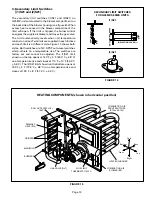

G25MV BURNER ASSEMBLY (shown in upflow position)

FIGURE 16

HOT SURFACE

IGNITOR

FLAME

SENSOR

MANIFOLD

ORIFICE

GAS VALVE

(GV1)

HEAT EXCHANGER

BURNER

UPPER

BURNER

MOUNTING

RAIL

LOWER

BURNER

MOUNTING

RAIL

BURNER BOX

BURNER BOX

TOP

ROLLOUT

SWITCHES (S47)

Front

Right

Bottom

Left

Back

PRIMARY LIMIT (S10)

VEST PANEL

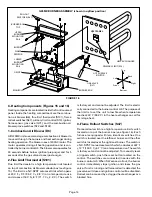

C–Heating Components (Figures 15 and 16)

Heating components are located inside the front louvered

panel. Inside the heating compartment are the combus-

tion air blower (B6), flue limit thermostat (S101), flame

rollout switches (S47), primary limit control (S10), ignitor,

flame sensor, gas valve (GV1), and the combustion air

blower prove switches (S72 and S102).

1–Combustion Air Blower (B6)

All G25MV units use a two stage combustion air blower to

move air through the burners and heat exchanger during

heating operation. The blower uses a 120VAC motor. The

motor operates during all heating operation and is con-

trolled by burner control A3. The blower also operates for

30 seconds before burner ignition (pre-purge) and for 5

seconds after the gas valve closes (post-purge).

2–Flue Limit Thermostat (S101)

Flue limit thermostat is a high temperature limit located

on top of combustion air blower collector box (see figure

15). The limit is a N.C. SPST auto-reset limit which opens

at 200

F + 5

F (93.3

C + 2.8

C) on a temperature rise

and closes at 160

F + 8

F (71.1

C + 4.4

C). The switch

is factory set and cannot be adjusted. The limit is electri-

cally connected to the burner control A3. The purpose of

the limit is to set the unit to low fire when temperature

reaches 200

F (93.3

C) in the heat exchanger on call for

first stage heat.

3–Flame Rollout Switches (S47)

Flame rollout switch is a high temperature limit switch

located on top of the burner box (see figure 16). Each

furnace is equipped with two identical switches. One

switch is located over the leftmost burner and the other

switch is located over the rightmost burner. The switch is

a N.C. SPST manual-reset switch which actuates at 267

F

+ 12

F (130.5

C + 6.7

C) on a temperature rise. The switch

is factory set and cannot be adjusted. To manually reset

a tripped switch, push the reset button located on the

control. The switches are connected in series with the

burner control A3. When S47 senses rollout, the burner

control immediately stops ignition and closes the gas

valve. If unit is running and flame rollout is detected, the

gas valve will close and ignition control will be disabled.

Rollout can be caused by a clogged heat exchanger or a

blocked flue.