Page 7

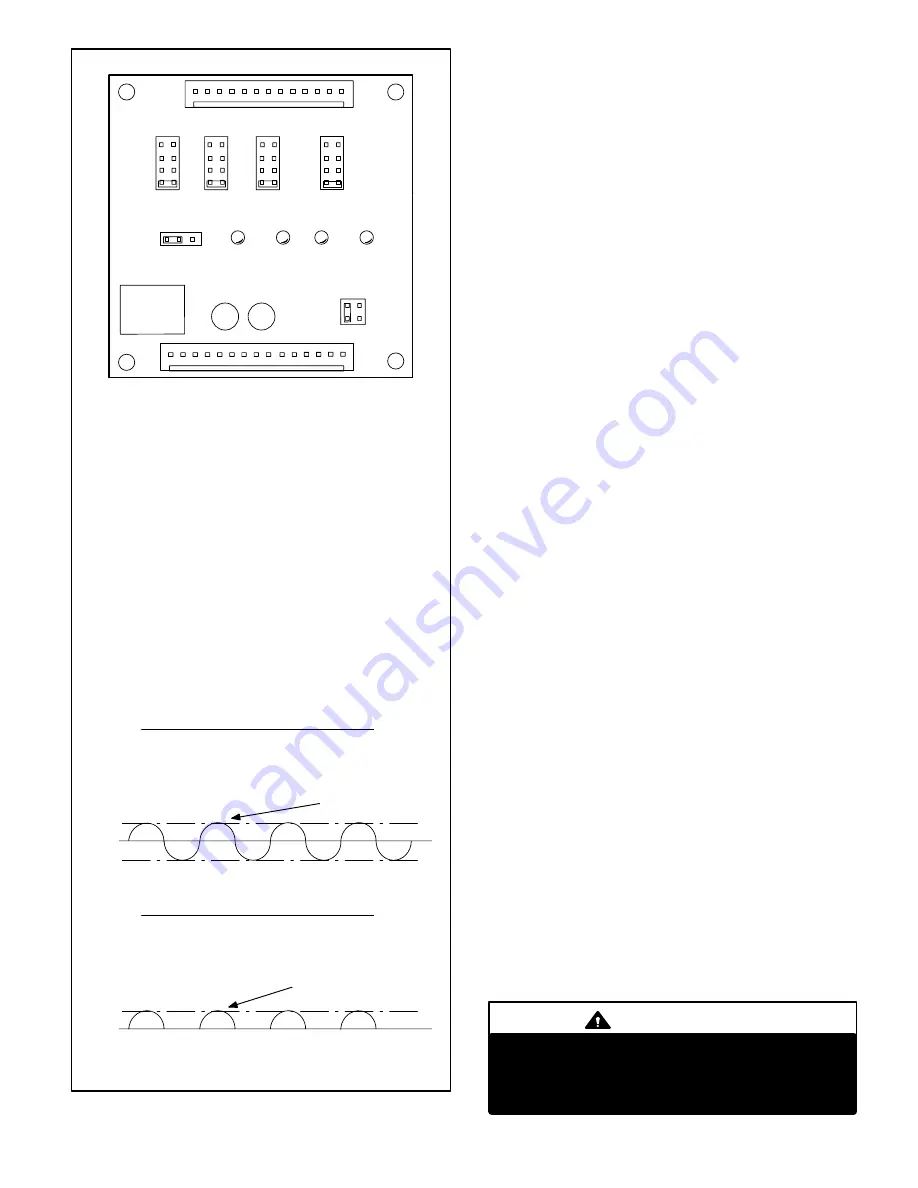

FIGURE 5

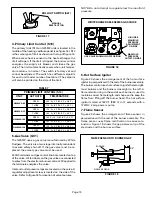

VSP2 BLOWER CONTROL BOARD (A24)

VOLTAGES INTO VSP2

VOLTAGES FROM VSP2 TO ELECTRONICALLY

CONTROLLED BLOWER MOTOR

34 volts

–34 volts

0 volts

Voltage across J73 pins 13 to 1 and 6 to 1 is 24VAC as shown here.

Refer to unit wiring diagram.

Voltage across J46 pins 6 to 3 and 1 to 3 is half-rectified AC as shown here.

Refer to unit wiring diagram.

Voltage across J73 pins 4 to 1 is approximately 15-20VDC (straight voltage) if

CCB is used. If Harmony is used a voltage of 0–25VDC should be present.

If CCB or Harmony is not used, pin 4 to 1 voltage is 21VAC.

Approx.

34 volts

0 volts

Voltage across J46 pins 8 and 9 to 3, is approximately 15-20VDC if CCB is used. If CCB

or Harmony is not used, pins 8 and 9 to 3 voltage is approximately 21VAC. If Harmony

is used a voltage of 0–25VDC should be present.

24VAC @ 60Hz.

24VAC Half-Rectified (DC Pulse)

@ 60Hz.

J46

HIGH

LOW

ADJUST

HEAT

CFM

HI/LOW

ON/OFF

HEAT

HTG.

BLOWER

1

2

DS2

DS3

DS1

DS4

1

2

3

4

1

2

3

4

1

2

3

4

TEST

–

+

NORM

210

150

90

270

J73

1

1

J73

PIN 1 - C - 24 VAC common.

PIN 2 - G - Input signal from thermostat’s fan signal.

PIN 3 - W2 - Input signal for second stage heat from the thermostat.

PIN 4 - DS - Input signal for the blower speed regulation.

PIN 5 - Limit - Input signal from the external limit.

PIN 6 - R - 24 VAC power to the thermostat.

PIN 7 - C - 24 VAC common.

Pin 8 - C - 24 VAC common.

PIN 9 - CI - Input signal from the fan limit control.

PIN 10 - CO - Output signal to the burner control.

PIN 11 - HT - Input signal from the fan limit control.

PIN 12 - ACC - 24 VAC accessory output.

PIN 13 - 24V - Input 24 VAC power for the VSP2-1.

PIN 14 - 24V - Input 24 VAC power for the VSP2-1.

PIN 15 - V - Input signal from the gas line.

J46

PIN 1 - Heat - Heat speed input signal to the ICM2 motor.

PIN 2 - C - 24 VAC common.

PIN 3 - C - 24 VAC common.

PIN 4 - High Tap - High Speed programming input.

PIN 5 - Low Tap - Low speed programming input.

PIN 6 - On / Off - On / off output signal to the ICM2 motor.

PIN 7 - Adjust Tap - ICM2 mode selection.

PIN 8 - Hi / Low - Speed regulate input signal to the ICM2 motor.

PIN 9 - Hi / Low - Speed regulate input signal to the ICM2 motor.

PIN 10 - Ref. V - ICM2 reference voltage.

PIN 11 - Heat Tap - Heating blower speed programming.

PIN 12 - C - 24 VAC common.

PIN 13 - cfm - Motor speed diagnostic signal.

Diagnostic LED Lights

ON/OFF

–DS3 indicates there is a demand for the blower

motor to run. When the

ON/OFF

LED–DS3 is lit, a demand

is being sent to the motor. In heating mode only, there is a

45 second fan “ON” delay in energizing

ON/OFF

LED–DS3. The light will not go off until adjustable fan

“OFF” delay has expired.

If

ON/OFF

LED–DS3 is on and both

HIGH/LOW

LED–DS1

&

HEAT

LED–DS2 are off, the motor will operate in

low speed.

If

HEAT

LED–DS2 is on, the blower is running in the heat

speed according to the “HEAT” jumper setting. The

HEAT

LED–DS2 comes on instantaneous and switches

off when the call for heat is satisfied.

NOTE–When the blower is in “OFF” delay mode, the

motor runs at low speed, therefore the

HEAT

LED–DS2

is off. It switches off when the call for heat is satisfied.

HIGH/LOW

LED–DS1 indicates whether the blower is

operating in high or low speed. When the light is off, the

blower is running in low speed according to the “LOW”

jumper setting. When

HIGH/LOW

LED–DS1 is on, the

blower is operating in high speed according to the

“HIGH” jumper setting.

CFM

LED–DS4 indicates the CFM the unit is operating,

according to the jumper settings. The light flashes

once for approximately every 100 CFM. For example, if

the unit is operating at 1000 CFM,

CFM

LED–DS4 will

flash 10 times. If the CFM is 2050,

CFM

LED–DS4 will

flash 20 full times plus one fast or half flash.

At times the light may appear to flicker or glow. This

takes place when the control is communicating with the

motor between cycles. This is normal operation.

The appropriate speed according to application and

CFM need is selected by moving jumper pins.

NOTE–On Harmony II zoning applications in the heating

mode, the highest speed obtainable is the same as the

highest cooling speed selection. Also, the heating speed

(heat jumper position) is only used when the primary limit

has been tripped. In non–zoning applications, refer to the

section on the VSP2–1 control.

Jumper Settings

IMPORTANT

Before changing jumper setting, make sure the

motor has completely stopped. Any jumper

setting change will not take place while the

motor is running.