Page 4

I–UNIT COMPONENTS (Figure 1)

G25MV unit components are shown in figure 1. The

blower controls, gas valve and burners can be accessed

by removing the front access panel. A separate blower

access door is located behind the front access panel.

Electrical control components are mounted to the

blower access door. Units are factory equipped with

bottom return air panels

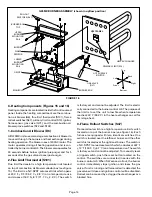

A–Blower Door Components (Figure 2)

Electrical burner control and blower control components

are located on the outside surface of the blower access

door. Jackplugs allow the blower door to be easily re-

moved for blower service.

Located on the blower door are the unit transformer

(T1), burner control (A3), VSP2 blower control board

(A24), and door interlock switch (S51).

1– Control Transformer (T1)

A transformer located on the blower door provides power

to the low voltage section of the unit. Transformers on all

models are rated 50VA with a 120V primary and a 24V

secondary. The transformer is protected by a 3.0 amp

circuit breaker.

2–Door Interlock Switch (S51)

A door interlock switch rated 16A at 125VAC is located

on the blower access door. The switch is wired in series

with line voltage. When the blower door is removed the

unit will shut down.

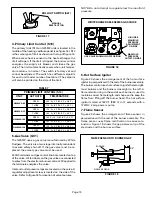

3– Burner Control (A3)

All G25MV units utilize a burner control manufactured

by RAM Electronics Corporation. The “RAM” board is

a printed circuit board which controls the gas valve,

combustion air blower and ignition. It also monitors

the flame, limit and gas valve operation. The board

utilizes both 120 and 24VAC. See figure 3. The board is

equipped with a diagnostic LED for use when trouble-

shooting the unit.

When the furnace is idle (blower off and no heating or

cooling demand), the diagnostic LED flashes at a

slow steady rate. On a call for heat, the diagnostic

LED begins flashing at a fast rate and the combustion

air blower is energized. The LED flashes different

codes to indicate problem conditions. The diagnostic

LED lights red (not flashing) to indicate control board fail-

ure. Table 1 shows how to interpret the other LED modes.

Pre-Purge

On a call for heat, the combustion air blower begins

operating. If the combustion air prove switch closes,

the combustion air blower continues to operate for

30 seconds (pre-purge) before allowing ignition. Pre-

purge allows the heat exchanger to be cleared of

combustion products and to introduce fresh air for

combustion. If the combustion air prove switch does

not close, the combustion air blower continues to run

indefinitely (until the prove switch closes).

Post-Purge

After a demand, the combustion air blower continues

to operate for 5 seconds (post-purge) before stopping.

Post-purge allows the heat exchanger to be cleared of

combustion products.

Ignition Control

The ignition control is a hot surface ignition control

module integral to the burner control. See table 2 and

figure 3. When there is a call for heat, the control delays

ignition until combustion air blower operation has been

proved and pre-purge period has elapsed. It then ener-

gizes a hot surface for 35 seconds. At the end of the 35

seconds the main gas valve opens on high fire. Trial for

ignition lasts for 7 seconds. At the same time, the control

begins monitoring the flame sensor. If the flame current

is too weak (less than 1 microamp) or if the burners do

not ignite (within the 7 second ignition trial), the control

will shut off the hot surface ignitor and the combustion

air blower and de-energize the gas valve. Flame current

should be between 1 and 5 microamps to keep the gas

valve open.

The control will attempt to ignite the burners up to two

more times. Each time the control restarts the ignition

sequence, it begins with a 30 second pre-purge. If flame

is not sensed after the third trial, the control locks out.

Lockout means that the control shuts off the gas valve,

spark and combustion air blower for 60 minutes. At the

end of 60 minutes the control completely resets and

will attempt ignition up to three times. The control

can be manually reset before the end of 60 minutes

by momentarily turning off power to the unit.

When flame is sensed, the indoor blower starts after a

45 second delay. Gas valve remains open and blower

continues to run until demand stops, flame sensor

senses loss of flame, a limit opens or the combustion

air prove switch opens. If any of these events occur

during a thermostat demand, the gas valve closes

and the diagnostic LED registers the error condition.