Page 24

NO

NO

NO

YES

YES

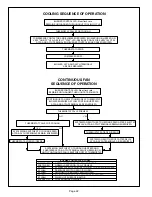

G25MV VSM BLOWER AND VSP2–1 BLOWER CONTROL BOARD

TROUBLESHOOTING FLOW CHART

DOES UNIT OPERATE?

CHECK:

1–UNIT POWER

2–INTERLOCK SWITCH

3–TRANSFORMER

4–LIMIT SWITCH

REPLACE VSP2–1.

END OF COOLING TEST

CHECK UNIT WIRING

AND IF CORRECT

REPLACE THE

VSP2–1.

COOLING MODE

NO

YES

YES

YES

IS BLOWER ON HIGH SPEED AND ARE DS1 AND

DS3 LIT? DOES THE “CFM” LED–DS4 LIGHT BLINK

ONCE FOR EVERY 100 CFM SELECTED IN THE

TABLES ON PAGE 2?

IN ADDITION TO R AND

G, JUMPER R AND DS.

IS 24 VOLTS PRESENT AT

TERMINAL “VSP2 #12” ON

BURNER CONTROL BOARD?

IS BLOWER ON LOW SPEED AND IS

“ON/OFF” LED–DS3 LIT? “CFM” LED–

DS4 LIGHT SHOULD BLINK ONCE FOR

EVERY 100 CFM SELECTED IN THE

TABLES ON PAGE 2.

CHECK UNIT WIR-

ING AND IF COR-

RECT, REPLACE

VSP2–1.

PLACE JUMPER ACROSS R AND G.

IS 24VAC ACROSS

R AND C?

NO

NO

YES

YES

DOES UNIT OPERATE?

CHECK:

1–UNIT POWER

2–INTERLOCK SWITCH

3–TRANSFORMER

4–LIMIT SWITCH

END OF TEST

REPLACE THE VSP2–1.

HEATING MODE

NO

YES

YES

YES

AFTER THE SELECTED

TIME, DOES BLOWER

TURN OFF?

PLACE “HTG. BLOWER”

JUMPER IN POSITION #1.

R AND W1 REMAIN JUMPERED.

1–CHECK UNIT WIRING AND IF

CORRECT, REPLACE VSP2–1.

PLACE “HTG. BLOWER” JUMPER IN POSITION #2.

PLACE JUMPER ACROSS R AND W1. WAIT 75

SECOND FOR PREPURGE AND FAN“ON” DELAY.

IS 24VAC ACROSS

R AND C?

2–BREAK AND REMAKE JUMPER

(R TO W1).

3–AFTER 30–35 SECOND

PURGE, IS 24VAC PRESENT

AT GAS VALVE?

REPLACE VSP2–1.

REMOVE JUMPERS

YES

NO

CHECK UNIT WIRING

AND IF CORRECT,

REPLACE VSP2–1.

NO

IS BLOWER ON LOW SPEED AND IS “ON/OFF” LED–

DS3 LIT? “CFM” LED–DS4 LIGHT SHOULD BLINK

ONCE FOR EVERY 100 CFM SELECTED IN THE

TABLES ON PAGE 2.

DOES BLOWER SHIFT TO HEAT SPEED

AND IS “HEAT” LED–DS2 ON? DOES

THE “CFM” LED–DS4 LIGHT BLINK

ONCE FOR EVERY 100 CFM SELECTED

IN THE TABLES ON PAGE 2?

NO

IS 24 VOLTS PRESENT AT

TERMINAL “VSP2 #12” ON

BURNER CONTROL BOARD?