Page 1

1995 Lennox Industries Inc.

LITHO U.S.A.

Corp. 9505–L2

G25MV

Service Literature

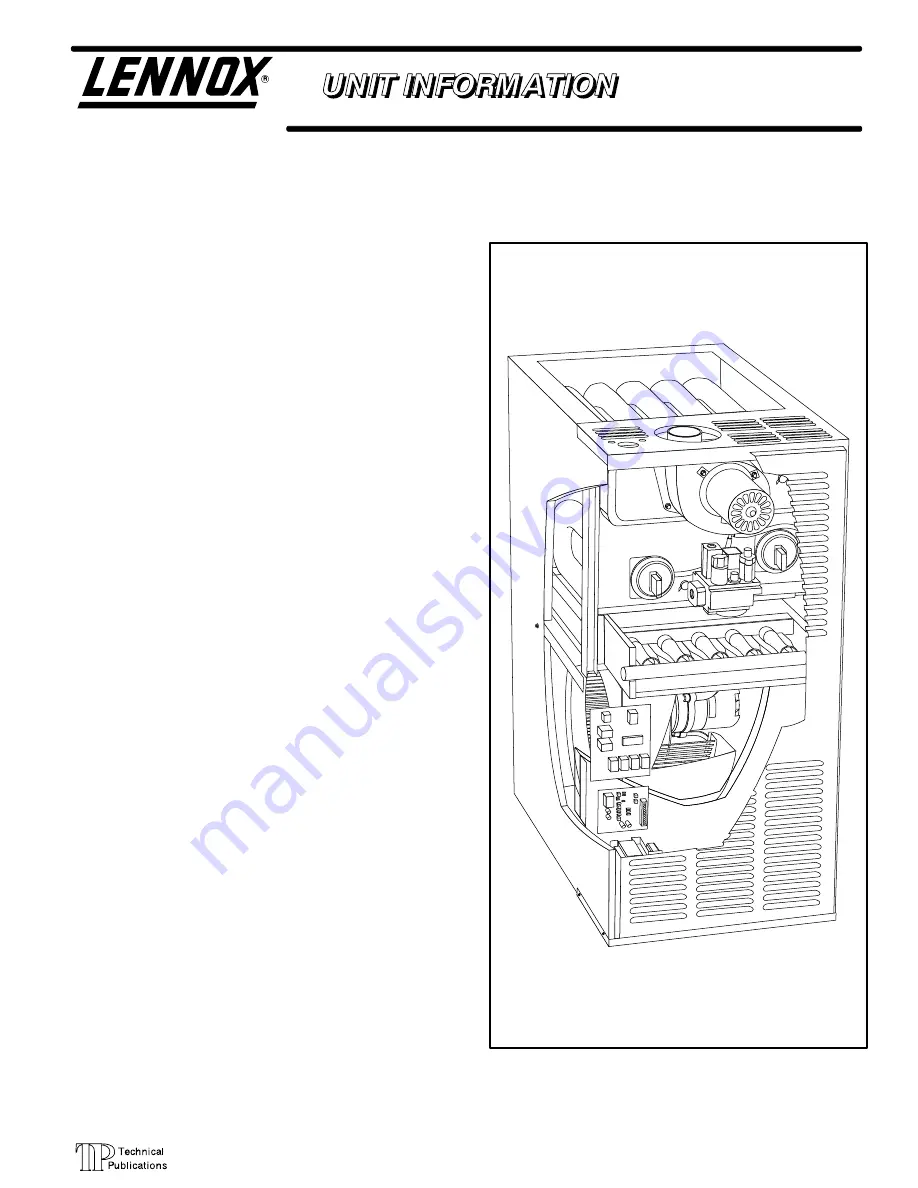

G25MV SERIES UNITS

G25MV series units are mid–efficiency gas furnaces

manufactured with tubular steel heat exchangers

formed of aluminized steel. G25MV units are available

in heating capacities of 60,000 to 120,000 Btuh (17.6 to

35.2 kW) and cooling applications from 1.5 through 5

tons (3.5 through 17.6 kW). Refer to Engineering Hand-

book for proper sizing.

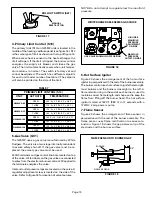

Units are factory equipped for use with natural gas. All

G25MV units use a hot surface ignition system. The

G25MV units meet the California Nitrogen Oxides (NO

x

)

Standards and California Seasonal Efficiency require-

ments. All units use a two stage gas valve along with a

two stage induced draft blower assembly. The gas valve

is redundant to assure safety shut–off as required by

A.G.A. or C.G.A.

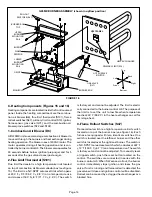

All G25MV units are equipped with an electronic vari-

able speed (VSM) fan motor. The VSM motor maintains

a specified air volume throughout the entire external

static range.

Units may be installed in upflow, downflow or horizon-

tal position. The heat exchanger is designed for upright

or horizontal use only. When the unit is installed in the

downflow position, the heat exchanger is field re-

moved and reinstalled so it is upright when the cabinet

is inverted. No field conversion is required when the

unit is installed in the horizontal position.

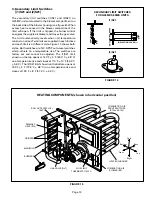

The heat exchanger, burners and manifold assembly

can easily be removed for inspection and service by sim-

ply disconnecting gas, unplugging wiring harnesses

and removing four screws holding the heat exchanger in

place. The heat exchanger slides out of the cabinet.

Information contained in this manual is intended for use

by Lennox service technicians only. All specifications

are subject to change. Procedures outlined in this manu-

al are presented as a recommendation only and do not

supersede or replace local or state codes.

G25MV