WARNING

THE INSTALLATION GUIDE MUST BE

USED WHEN INSTALLING OR REIN-

STALLING AUTOMATIC SLACK AD-

JUSTER. FAILURE TO DO SO MAY RE-

SULT IN IMPROPERLY ADJUSTED

BRAKES WHICH MAY CAUSE BRAKE

DAMAGE OR LEAD TO BRAKE FAIL-

URE.

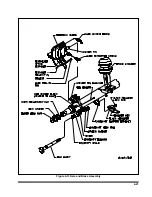

a. Operational Check (See Figure 4-14)

1.

Block wheels to prevent vehicle from

rolling.

2.

Check that the push rod is fully retracted,

apply air to release spring brake.

3.

Turn adjustment hex counterclockwise to

create an excessive clearance condition.

(A ratcheting sound will occur.)

4.

Make a full service brake application. On

release, allow sufficient time for brake to

fully retract. During the brake release,

observe rotation of the adjustment hex

(attach a wrench on the hex to make this

movement easier to see). This rotation

indicates that an excessive clearance

condition has been determined by the slack

adjuster, and it is making an adjustment to

compensate. On each subsequent brake

release the amount of adjustment and push

rod travel will be reduced until the desired

clearance is achieved

5.

The push rod stroke should be 1 1/2" to 2"

with an 100 to 105 PSI service brake

application.

6.

Measure the movement of the push rod

from the completely released position to

the applied position by marking the push

rod where it exits the air chamber before

and after application.

7.

If the brakes have been running tight, the

control arm location should be checked.

WARNING

IF THE ADJUSTER APPEARS NOT TO

BE OPERATING, CHECK THE OTHER

BRAKE COMPONENTS FOR PROPER

FUNCTION AND ELIMINATE ANY BIND-

ING. RECHECK THE AUTOMATIC

SLACK ADJUSTER. IF THE ADJUSTER

IS NOT FUNCTIONING, THE UNIT

MUST BE REPLACED BECAUSE FAIL-

URE OF PROPER ADJUSTMENT

FUNCTION WILL RESULT IN LOSS OF

BRAKES.

b. Replacing Slack Adjuster (See Figure

1.

Chock wheels to prevent vehicle from

rolling. Release spring and service brake.

Air chamber push rod must be

fully

released.

2.

To maintain a fully released parking brake,

a minimum of 105 psi reservoir pressure

must be maintained. If air pressure is not

available the spring brake must be

manually caged.

4-23

Figure 4-14 Slack Adjuster

Summary of Contents for 600B Series

Page 8: ......

Page 12: ......

Page 14: ...3 2 Figure 3 1 Front Trailer Terminology Figure 3 2 Rear Trailer Terminology...

Page 18: ...3 6 Figure 3 4 Hydraulic Controls...

Page 26: ...3 14 Figure 3 7 Steps for Loading and Unloading...

Page 32: ...3 20 Figure 3 10 Dock Leveler Operation...

Page 38: ...3 26 Figure 3 14 Rear Impact Guard and Antilock Brake System...

Page 42: ...4 2 Figure 4 1 Lubrication Points...

Page 48: ...4 8 Figure 4 3 600B Wiring Diagram...

Page 49: ...4 9 Figure 4 4 Remote Wiring Diagram...

Page 52: ...4 12 Figure 4 5 Tandem Axle Air Ride Suspension System Figure 4 6 Air Ride Height Adjustment...

Page 54: ...4 14 Figure 4 7 Triple Axle Air Ride Suspension System...

Page 57: ...4 17 Figure 4 9 Checking Axle Alignment Figure 4 10 Examples of Camber...

Page 61: ...4 21 Figure 4 13 Axle and Brake Assembly...

Page 71: ...4 31 Figure 4 21 Dock Leveler Leg Assembly...

Page 73: ...4 33 Figure 4 22 Crank Landing Gear Assembly...

Page 84: ...NOTES 5 10...