3

Safety logic module FE201

21 of 70

Hardware R2.2.8 11.98.02 en

3

Safety logic module FE201

Incorrect settings of the DIP--FIX switches X1 --X10 can lead to dangerous

malfunctions of the robot in certain circumstances ! Before switching the

controller on, it is therefore imperative to check the settings of the DIP--FIX

switches X1 -- X10 again according to the adjustment instructions in this

section!

If these instructions are not observed there is a risk of extensive damage to the

robot !

3.1

Function blocks

Module FE201 serves to implement the safe switch--off function and the Drives ON circuit.

It comprises:

-- Voltage monitoring for 27 V

-- Dual--channel EMERGENCY STOP circuit

-- EMERGENCY STOP delay

-- Dual--channel user safeguard (operator safety and enabling circuit)

-- Operating mode switchover (Test / Automatic)

-- Drives ON circuit

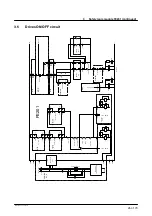

3.1.1

Settings

To ensure the safe functioning of the robot, it must be checked that the DIP--FIX

switches have the following settings before the robot is put into operation:

--X1 -- X6

These DIP--FIX switches serve the purpose of setting the EMERGENCY STOP delay in

Automatic mode.

X1 and X4

X2 and X5

X3 and X6

Emergency Stop

X1 and X4

X2 and X5

X3 and X6

Emergency Stop

delay

closed

closed

closed

0.5 s

closed

closed

open

0.7 s

closed

open

open

1.0 s

open

open

open

1.3 s

(default setting)

--X7 -- X9

X7 -- X9

External axes

closed

not present (default setting)

open

present

--X10

(version B only)

Position “b” (default setting)

Emergency Stop switch--off without path--

oriented braking

Position “a”

Emergency Stop switch--off with path--

oriented braking

Summary of Contents for KR C1

Page 1: ...Hardware R2 2 8 11 98 02 en 1 of 70 SOFTWARE KR C1 Hardware Release 2 2...

Page 30: ...Hardware 30 of 70 Hardware R2 2 8 11 98 02 en Fig 13 Circuit diagram X931 X604...

Page 32: ...Hardware 32 of 70 Hardware R2 2 8 11 98 02 en Fig 15 Inputs...

Page 34: ...Hardware 34 of 70 Hardware R2 2 8 11 98 02 en...

Page 35: ...35 of 70 Hardware R2 2 8 11 98 02 en...