| 29

EN

TIG AC

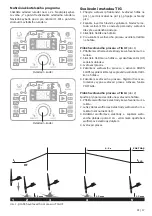

- Setting END CURRENT function

(end current)

The function indicates the current value at which the

welding process ends. Together with the DOWN SLOPE

function, it prevents crater formation at the end of the

weld. Activation is done by pressing the control n-coder

one after the other.

OFF

N-coder

Waveform switching

button

TIG HF

AC - square AC - sinusoid

TIG AC

- Setting POST GAS function

The function ensures protection of the weld after the

welding process is completed and at the same time it

cools the tungsten electrode. The low duration of the

function can affect the ignition quality of the arc due to

oxidation of the electrode. Activation is performed by

pressing the control n-coder one after the other.

OFF

N-coder

Waveform switching

button

TIG HF

AC - square AC - sinusoid

TIG AC

- Setting DUTY CYCLE AC function

The function allows setting the ratio of negative (wel-

ding) and positive (cleaning) waves. Increasing the value

increases the cleaning effect and increases the thermal

load of the tungsten electrode. Depending on the dia-

meter of the tungsten electrode used, it is necessary

to select the value of the function so that the tungsten

electrode does not overheat and the ball is formed at its

end. As a result of the formation of a ball, the welding arc

becomes unstable and the possibility of controlling the

arc direction is lost. If black spots are visible in the weld

pool, the function value must be added to remove these

impurities. By setting a lower function value, the pene-

tration of the material increases, but also the cleaning

effect is reduced. This may result in poor weld quality.

Activation is performed by pressing the control n-coder

one after the other.

OFF

N-coder

Waveform switching

button

TIG HF

AC - square AC - sinusoid

TIG AC

- Setting FREQUENCY AC function

The function allows setting the frequency - exchange

negative (welding) and positive (cleaning) waves. By in-

creasing the frequency AC reduces the material‘s ther-

mal deformation and narrows weld baths. Activation is

performed by pressing the control n-coder one after the

other.

OFF

N-coder

Waveform switching

button

TIG HF

AC - square AC - sinusoid