8

English

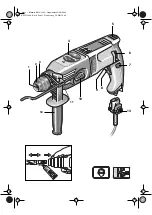

BMH 1000

Before any work on the machine itself, pull the

mains plug!

Connect the mains cable module to the handle. The

plug must latch.

Use the mains cable module provided only for

Kress Electro-Tools. Do not attempt to operate

other machines with the module.

Use only an original Kress mains cable module that is

at least of heavy rubber sheathed cable (Code desig-

nation H07 RN-F).

Check before putting into operation that the mains

voltage agrees with the voltage specified on the

nameplate of the machine.

SWITCHING ON/OFF

Press or release the on/off switch 8.

The on/off switch can be locked on with the locking

button 7. To release, briefly press and release the on/

off switch 8.

MECHANICAL GEAR SELECTION

With the gear selector/rotation stop switch 4, one of

three positions can be selected.

1 = Lower speed range: Hammer drilling, drilling

with normal twist drills in wood/metal over 8 mm dia.

and mixing work.

2 = Higher speed range: Drilling with normal twist

drills to 8 mm dia.

= No rotation: Light chiselling work.

The switch-over can best be performed at a standstill.

Please observe that the gear selector/rotation stop

switch 4 can be switched only one step at a time. Only

after the on/off switch 8 is actuated and the machine

starts does the gear box shift to the selected mode.

The gear selector/rotation stop switch 4 can only then

be switched again to the next position.

DRILLING - IMPACT DRILLING

For drilling, place the selector 10 in the

position.

For impact drilling, set to

.

The switch-over can best be performed at a standstill.

Only after the on/off switch 8 is actuated and the

machine starts does the gear box shift to the selected

mode.

Note: Left rotation when impact drilling damages the

drill. Switch off the impact mechanism for diamond

crown drilling or for mixing work.

For chiselling work, set the selector 4 to the

posi-

tion.

When hammer drilling, use exclusively drills with

hard metal inserts and SDS-Plus shafts. The use of

commercially available masonry drills with cylindrical

shafts by means of the adapter 14 and the normal drill

chuck in conjunction with the pneumatic impact mech-

anism is not possible.

SPEED CONTROL

With the on/off switch 8, the speed

can be continuously varied. With

light pressure on the on/off

switch 8, the machine begins to

rotate slowly; with increased pres-

sure, the speed increases.

SPEED PRESELECTION

With the knob 9, the speed in the gears 1 and 2 can

be continuously preselected also when the machine is

running.

Position A = lowest speed.

Position G = highest speed.

FULL WAVE ELECTRONIC SYSTEM WITH

TACHOMETER

The built in full wave electronic system with tachome-

ter maintains a constant rpm speed.

The electronic system also has a gradual start up

feature.

Even if the trigger-switch is fully depressed, the

machine will only reach its full rpm speed after approx.

1 second. This permits smooth drilling even when

working with sensitive materials.

ROTATIONAL DIRECTION SWITCHING

Operate the rotational direction

switch 6 only when the machine is

at a standstill!

Take hold of the rotational direction

switch 6 on both sides.

Right rotation: Set the rotational direction switch 6

to “R”.

Left rotation:

Set the rotational direction switch 6

to “L”.

Important!

Press the rotational direction

switch 6 through to the stop on the

housing each time, i. e., until it can

be felt to latch.

If the rotational direction switch 6 is set between the posi-

tions “R” and “L”, the machine cannot be switched on.

5

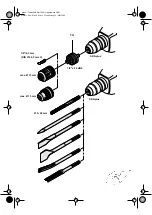

Mounting the Auxiliary Handle and

the Mains Cable Module

6

Putting into Operation

BMH 1000 - Buch Seite 8 Donnerstag 29. Mai 2006

Operate the machine only with the auxiliary han-

dle 12. Place the auxiliary handle on the clamping

collar and tighten with the clamping screw.