BMH 1000

English

7

Application

The Pneumatic Drill Hammer can be used universally

for impact drilling, for light chiselling work in masonry

and for drilling as well as screwdriving in wood, metal

and plastic.

Before putting the machine into operation, read

through these operating instructions completely and

observe the safety instructions contained therein as

well as those in the enclosed booklet on general

safety instructions for electro-tools.

If the mains cable is damaged while working, pull

the mains plug immediately.

Never work with a damaged mains cable.

Wear protective glasses, hearing protection, pro-

tective gloves and sturdy shoes.

1

Safety Instructions and

Accident Prevention

2

Illustration

3

Technical Data

Pneumatic Drill

Hammer

BMH 1000

Article number

0428 3512

Input power

1000 W

Output power

600 W

Electronic control

•

Full wave electronic

•

No-load speed

1st Gear

125-875 RPM

2nd Gear

250-2000 RPM

Speed under load

1st Gear max.

800 RPM

2nd Gear max.

1850 RPM

No-load impact rate

4700/min max.

Load hammer blows

4300/min

Right/Left rotation

•

Clamping collar dia.

43 mm

Euro standard

Tool holder

SDS-Plus

Drill dia., max.

Steel

16 mm

Light metal

25 mm

Wood

50 mm

Hammer drilling in

conctrete

28 mm

Recommended

hammer drilling

range

4-16 mm

Screw dia., max.

Wood

8 mm

Sheet metal

6.3 mm

Corner measure

42 mm

Weight

2.8 kg

Protection class

II/

4

Noise/vibration information

BMH 1000 - Buch Seite7 Donnerstag 29. Mai 2006

Measured values determined according to

EN 60 745.

Typically the A-weighted noise levels of the machine

are: sound pressure level 96 dB (A); sound power level

107 dB (A). Measurement uncertainty

K = 3 dB.

Wear hearing protection!

The typically weighted acceleration is 7,8 m/s².

Do not work with materials containing asbestos.

Do not carry the machine by the cable.

The mains receptacles in the working area must be

protected by a residual current circuit breaker (RC).

For the attachment of identification markings on the

machine, do not drill into the housing. The protec-

tive insulation would be shorted. Use stickers.

When the drill unexpectedly jams, the machine

kicks back. Therefore, always take a secure stance

and hold the machine firmly with both hands.

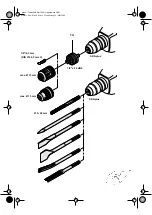

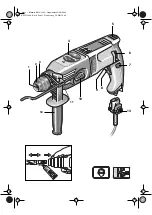

1 Tool holder

2 Dust protection cap

3 Unlocking collar

4 Gear selector/Rotation stop switch

5 Ventilation slots

6 Rotational direction switch

7 Locking button for on/off switch

8 On/Off switch

9 Speed selection knob

10 Drilling/Impact drilling selector

11 Holder for depth stop

12 Auxiliary handle

13 Latch for mains cable module

14 Adapter for screwdriver bits/drill chuck

Accessories illustrated or described are not

always included as standard delivery items.

Wear hearing protection.

Exposure to noise

can cause hearing loss.

Use the auxiliary handles supplied with the

machine.

Loss of control can cause personal