AccurioPress C2070series

6-27

6.2

Image Quality Adjustment

6

6.2.2

Daily image quality management (Calibration)

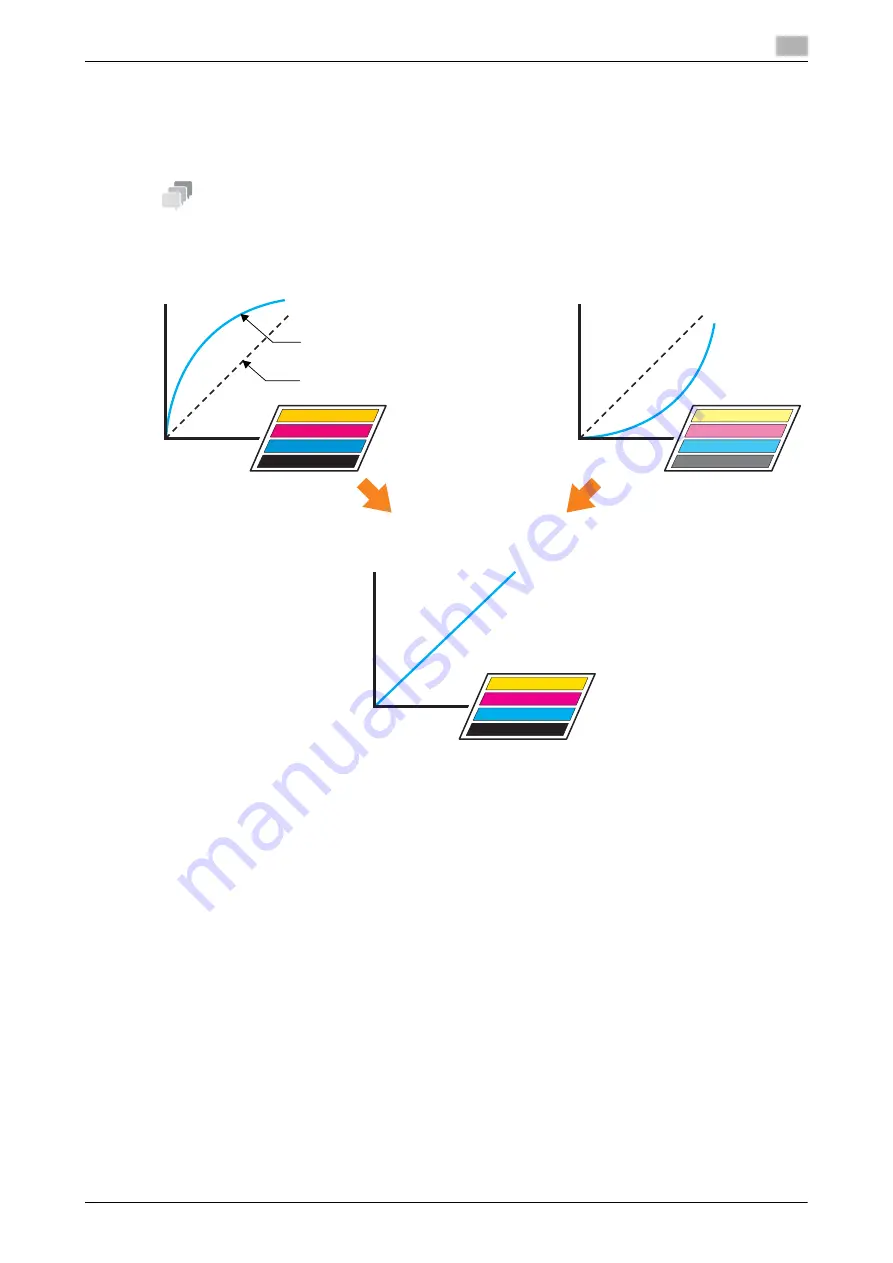

You can maintain the color image quality by executing calibration at the appropriate timing.

The reference value (target) of the entire printing system is registered in advance. Compare this reference val-

ue with the current measurement value to adjust the difference, and correct the printing density.

Tips

The reference image quality must be specified before carrying out daily quality management. Before this pro-

cessing, adjust the reference image quality (page 6-40).

Adjust the printing density to the reference value

Consistent printing result

When print density is high

When print density is low

Current measurement value

Reference value of target

Ou

tp

u

t (

%

)

Ou

tp

u

t (

%

)

Ou

tp

u

t (%)

Input (%)

Input (%)

Input (%)

Summary of Contents for AccurioPress C2060

Page 2: ......

Page 6: ...Contents 4 AccurioPress C2070series ...

Page 7: ...1 Introduction ...

Page 8: ......

Page 16: ...1 10 AccurioPress C2070series Make a Note about This Machine Information 1 1 6 ...

Page 17: ...2 Before Getting Started ...

Page 18: ......

Page 32: ...2 2 Available Operations in this Machine 2 AccurioPress C2070series 2 16 ...

Page 33: ...3 Let s Make Prints ...

Page 34: ......

Page 37: ...4 Installing Software ...

Page 38: ......

Page 57: ...5 Basic Operations ...

Page 58: ......

Page 75: ...6 Maintaining the Finishing Quality ...

Page 76: ......

Page 119: ...7 Troubleshooting ...

Page 120: ......

Page 136: ...7 7 If you forget the administrator password 7 AccurioPress C2070series 7 18 ...

Page 137: ...8 Appendix ...

Page 138: ......

Page 184: ...8 6 Maximum paper size and printing area 8 AccurioPress C2070series 8 48 ...