Quick Reference Operating Instructions

7E6174 – 16FEB01

2– 9

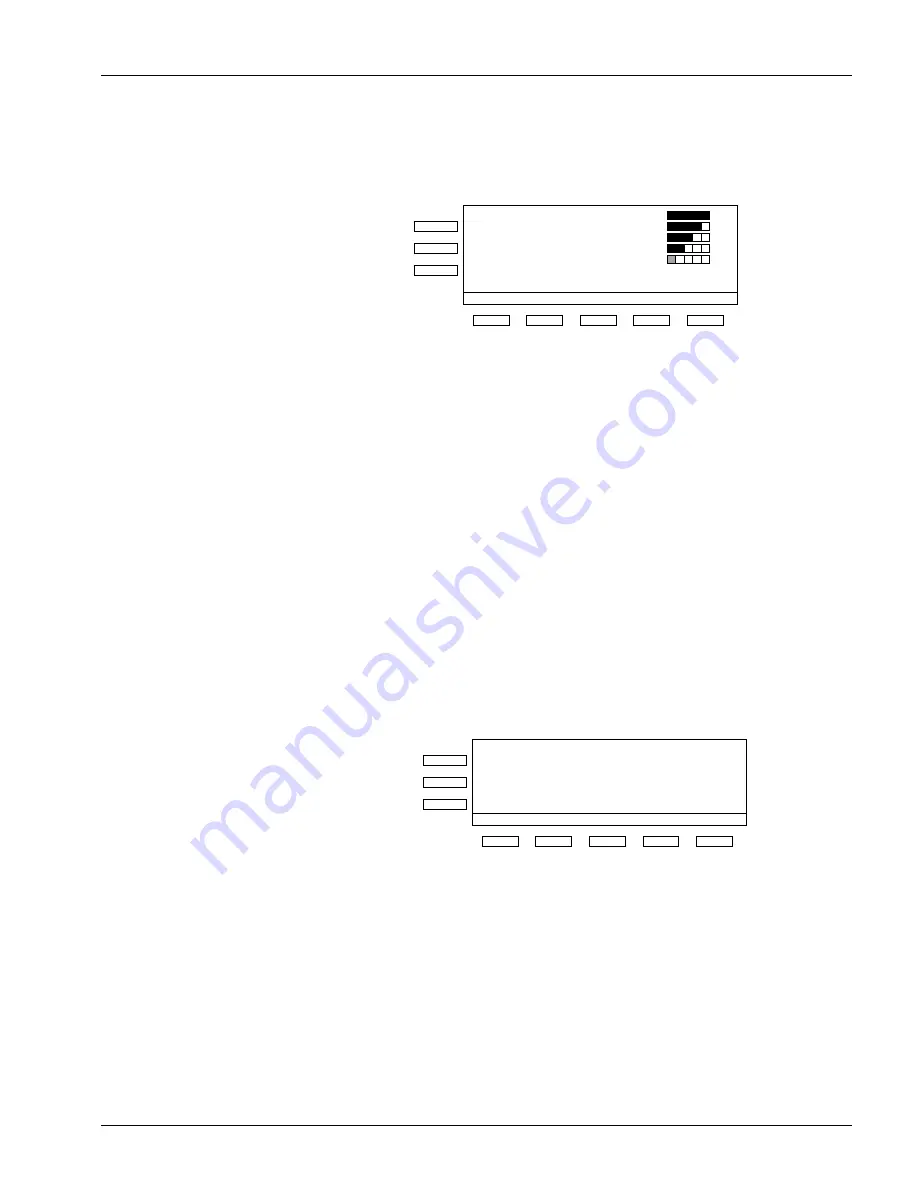

The Cassette will be pulled into the Multiloader and the orange status light will

illuminate. The following will be displayed.

This indicates that a Cassette is inside the Multiloader and an unload/load operation

cycle is in progress.

After unloading an exposed film and loading unexposed film, the Cassette will be

returned. When the Cassette is removed the green status light will illuminate. The

orange light will remain illuminated until the film exits the Multiloader.

The display will return to the main menu. The Multiloader is ready for the next

operation.

If the green and orange status lights are illuminated, a film is still inside the

Multiloader, but the system is ready to accept the next Cassette.

If the red status light flashes and the audible alarm sounds, remove the Cassette and

press CLEAR to cancel the message on the Display Panel.

The warning message must be cancelled by pressing the soft switch marked CLEAR,

after the Cassette has been removed.

PROC

SERIAL

LOAD

UNLOAD

FUNC

*

M A G. 1:

M A G. 2:

M A G. 3:

M A G. 4:

M A G. 5:

M A G. 6:

M A G. 7:

8 x 10 in

35 x 43 cm

35 x 43 cm

18 x 24 cm

24 x 30 cm

24 x 30 cm

18 x 24 cm

V

X

X

X

X

M

M

#2

?

EMPTY

ORANGE

GREEN

RED

ON

Soft Switches

Status Lights

H186_8501AC

H186_8504AC

RETURN

CODE

"BEEP"

Flashing

ON

RED

GREEN

ORANGE

CLEAR

CASSETTE NOT LOADED

Summary of Contents for X-OMAT 7000

Page 4: ...4 16FEB01 7E6700...

Page 6: ...6 16FEB01 7E6174...

Page 20: ...Introduction 1 14 16FEB01 7E6174...

Page 32: ...Quick Reference Operating Instructions 2 12 16FEB01 7E6174...

Page 48: ...Overview 3 16 16FEB01 7E6174...