Operating manual 17.410+411

Pos.: 20

Dateiname

Firma

Datum

Rev

BK-DH 700 x 1000 eng.doc

BRUKS-KLÖCKNER

27.02.09

00

Seite 52 von

61

9.2

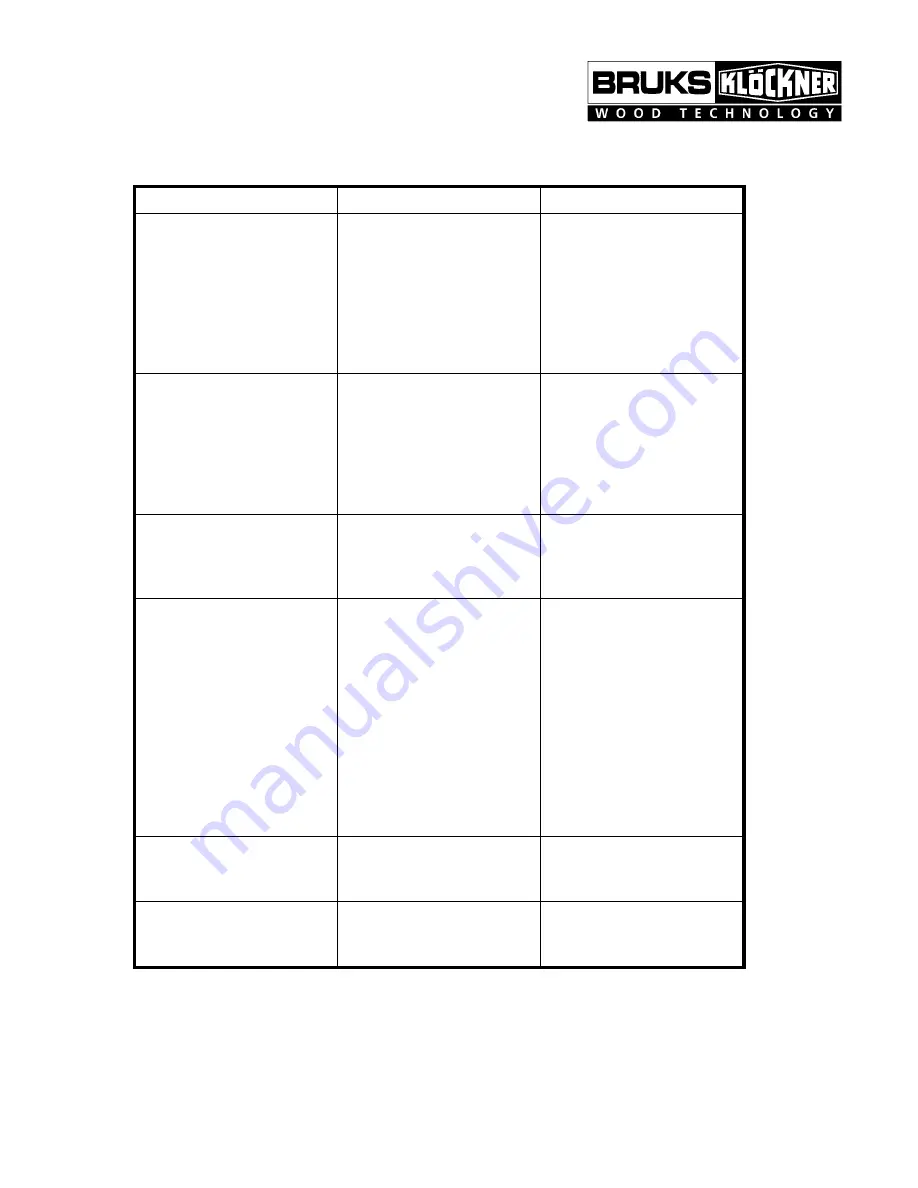

Problems with the machine

problem

possible cause

suggested solution

rotor slow down

automatic feed control

defective

dull knives

take away conveyor of

inadequate capacity

check controls and repair

if necessary

grind knives

(see chap-

ter „inspection and

maintenance works“)

increase capacity

frequent activation of the

load control

dull knives

load control defective

main motor too small

chipping volume too high

regrind or change knives

check control and repair

if necessary

check and increase mo-

tor power

reduce volume

machine vibrates

imbalance of rotor due to

uneven ground knives

grind all knives in one set

to equal width

(see chap-

ter „inspection and

maintenance“)

unsatisfactory indeed

teeth of feedrolls worn

oil pressure (p3) too high

or too low

gas pressure (p1) wrong

feedroll carrier lowers too

slowly

replace feedrolls

adjust oil pressure (p3)

(see chapter „inspec-

tion and maintenance“)

adjust gas pressure (p1)

(see chapter „inspec-

tion and maintenance

works“)

adjust lowering speed

(see chapter „installa-

tion“)

feedroll carrier stops too

hard

feedroll carrier drops too

fast

adjust lowering speed

(see chapter „installa-

tion“)

gear motor cannot start

lower feedrolls

feedrolls jammed with

material between feedroll

and troughside

remove material re-adjust

trough side with adjusting

screws