119

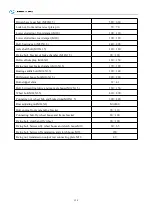

No.

Pressure

Description

Analysis

Remedy

5

The high pressure is higher

than the normal value and

the low pressure is nearly

to zero or negative value

and the gauge swing

seriously

The air sent to the bus

sometime cold and

sometimes warm and the

inspection glass looks

yellow

Too much water

in the system desiccators

reaching the saturation

the frosting water blocked

the expanding valve

Change the desiccators

and make the vacuum

repeatedly and then

re-fill the refrigerant

6

The low pressure is much

higher than the normal

value and the high pressure

is a little bit higher than the

normal value

Cold is in sufficient

The condenser blower

doesn’t work normally or

there is blockage in the

condenser radiator

Check the electric

circuit diagram or

cleaning the condenser

7

The high are low and low

pressure are higher than

the normal values

The cold air is insufficient

Compressor interior

failure

Repair or change the

compressor

8

The high and low pressure

are lower than the normal

value

Evaporator wind flow is

insufficient

Evaporator blower not

running or low in

efficiently or the radiator

of the evaporator blocked

Check the electric

circuit diagram or clean

the evaporator radiator

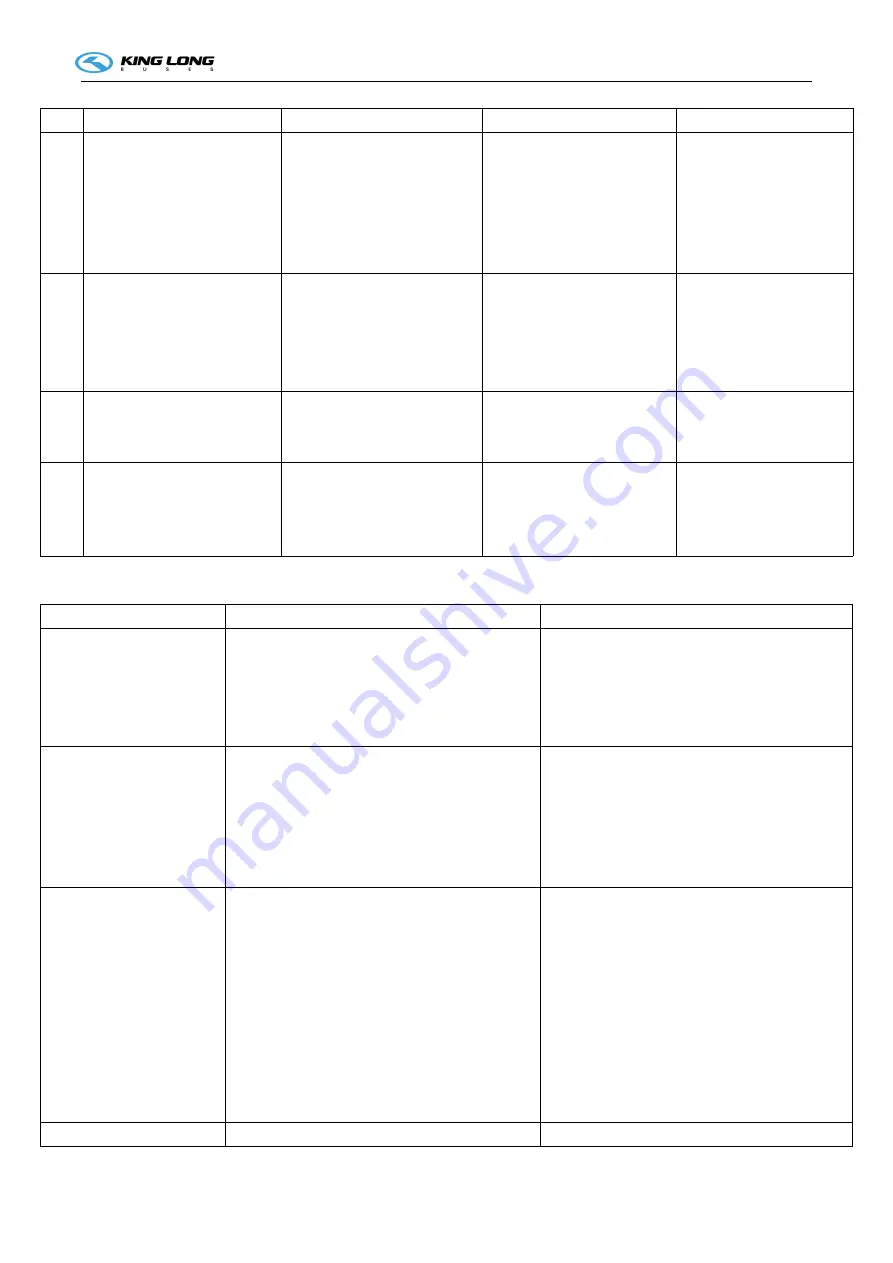

9. Electric system trouble and remedy

Fault symptom

Possible cause

Eliminating method

the power lamp on the

control panel not light

1. + no power supply;

2. D+ not connected well;

3. harness not tight;

4. control unit failure;

1. generator D+ no output, exchange the

generator and repair

2. reconnect the cable D+;

3. reconnect the harness;

4. change the control panel or repair;

malfunction light on the

control panel light up

1. system pressure error;

2. pressure switch defective;

3. pressure switch harness not connected

well;

4. harness connection not well;

5. control panel failure;

1. to connect the manifold gauge and

eliminate the malfunction;

2. change the pressure switch and repair;

3. reconnect the pressure switch;

4. harness connection;

5. change the control panel or repair;

refrigerant lamp is not

lighted up

1. defrost sensor failure or connection

problem;

2. temperature control sensor failure or

connection problem;

3. temperature control sensor installation

position not good ;

4. temperature control switch defective;

5. harness connection not reliable;

6. Control panel defective

1. change the defrost sensor or connect

the cable again;

2. change the temperature control or

connect the harness again;

3. re-install the temperature control into

the correct position;

4. change the temperature control switch

or repair;

5. harness connection again;

6. change the control panel or repair;

condenser fan not

1. malfunction lamp light up;

1. check the problem according to the