-

6

Danger

Risk of injury! The main switch is to be switched off while carrying out any repairs or maintenance jobs.

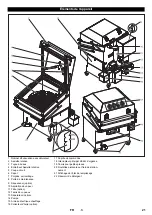

1 Shavings sieve

Î

Pull the shavings sieve out toward the

top and clean it under running water.

You can enter into a maintenance contract

with the concerned Kaercher Sales Office

for the machine.

Danger

Scalding danger! The detergent liquid must

have cooled down completely before drain-

ing it off.

Î

Open the drain-off tap on the lower side

of the device.

Î

Drain off the detergent liquid.

Î

Add new detergent liquid; see section

on start-up.

Î

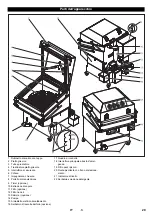

Turn off the appliance.

Î

Turn the filter using a filter spanner.

Î

Take out the filter inlay.

Î

Clean or replace the filter inlay.

Î

Install a new filter inlay.

Î

Tighten the filter again.

Maintenance and care

Maintenance schedule

Time

Activity

Assembly affected

Performance

of whom

daily

Check function

Safety button

Briefly open the machine hood with the machine

running (caution, steam!). The pump and the

turntable must switch off. If this is not the case,

turn the device off and inform Customer Service.

Operator

Check filling level. Fill level indicator in the deter-

gent container

Refill water.

Operator

Oil collection basin

Dispose off the oil according to applicable regu-

lations.

Operator

Check small

parts and shav-

ings sieve.

Small parts and shavings sieve Clean small parts and shavings sieve.

Operator

weekly or after 40

operating hours

Visual inspection Hoses, pump.

Check the hoses inside and outside of the ma-

chine and the pump for leaks.

Call customer service in case of leaks.

Operator

Check filter (op-

tional).

Filter after the pump.

Install a new filter inlay.

Operator

Check function

Rotating plate

Check the turntable for easy movement.

Call customer service in case of unsmooth

movement.

Operator

Visual inspection Nozzles in the nozzle pipes.

Replace damaged or worn out nozzles immedi-

ately.

Operator

monthly or after 200

operating hours

Check deter-

gent liquid.

Water container, filter and noz-

zle pipes.

Replace detergent fluid as required. Clean the

water container, filter and nozzle pipes.

Operator

half-yearly or after

1000 operating

hours

check, clean

Entire device.

Visual inspection of the device; check hoses and

connections to see that they are not leaky.

Customer

Service

Clean the shavings sieve

Maintenance contract

Maintenance Works

Replacing detergent liquid

Do not let the polluted detergent liquid

come untreated in contact with soil, water

or the sewage system. Please follow the

corresponding regulations in the respec-

tive country.

Cleaning the filter (optional)

16

EN

Summary of Contents for PC 60T

Page 2: ...2...

Page 92: ...2 0 15 Ohm 3 92 EL...

Page 93: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 Not Aus 19 20 21 22 93 EL...

Page 94: ...4 1 2 3 AUTO OFF 1 ON 4 5 6 94 C 7 AUTO OFF 1 ON 8 80 C 130 kg 30 3 1 2 3 OFF 94 EL...

Page 95: ...5 Am besten vor Arbeitsbeginn durchf hren 1 A 5 B C1 1 C2 2 C D E F G 1 2 H I 1 95 EL...

Page 96: ...6 1 K rcher 40 200 1000 96 EL...

Page 97: ...7 0 97 EL...

Page 108: ...2 0 15 BGV A3 108 RU...

Page 109: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 109 RU...

Page 110: ...4 1 2 3 OFF 1 ON 1 4 5 6 94 C 7 OFF 1 ON 1 8 80 C 130 30 1 2 3 OFF 110 RU...

Page 111: ...5 Am besten vor Arbeitsbeginn durchf hren 1 A 5 B C1 1 C2 2 C D E F G 1 2 H I 1 111 RU...

Page 112: ...6 1 Karcher 40 200 1000 112 RU...

Page 113: ...7 0 113 RU...

Page 180: ...2 30 mA IEC 60364 1 0 15 Ohm BGV A3 180 BG...

Page 181: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 181 BG...

Page 182: ...4 1 2 3 AUTO OFF 1 ON 4 5 6 94 C 7 AUTO OFF 1 ON 8 80 C 130 30 3 1 2 3 OFF 182 BG...

Page 183: ...5 Am besten vor Arbeitsbeginn durchf hren A 5 B C1 1 C2 2 C OK D E F G 1 2 H I 1 T o 183 BG...

Page 184: ...6 1 K rcher 40 200 1000 184 BG...

Page 185: ...7 0 185 BG...

Page 212: ...2 0 15 BGV A3 212 UK...

Page 213: ...3 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 213 UK...

Page 214: ...4 1 2 3 OFF 1 ON 1 4 5 6 94 C 7 OFF 1 ON 1 8 80 C 115 30 3 1 2 3 OFF 214 UK...

Page 215: ...5 Am besten vor Arbeitsbeginn durchf hren A 5 B C1 1 C2 2 C OK D E F G 1 2 H I 1 215 UK...

Page 216: ...6 1 K rcher 40 200 1000 216 UK...

Page 217: ...7 0 217 UK...

Page 219: ......