LRWMANUAL 0918

KAM CONTROLS, INC.

10

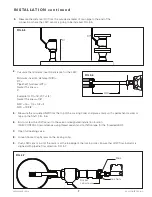

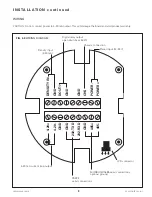

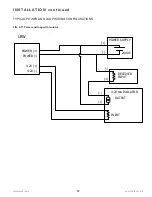

I N S TA L L AT I O N c o n t i n u e d

POWER (–)

GND

POWER (+)

24-30 VDC

DENSITY IN

From mass flow or densitometer.

GND

4-20 mA (–)

Current output, source powered. Set to requisite percent water at factory.

4-20 mA (+)

DIG OUT (–)

Alarm or relay (digital contact closure / max 50 W)

DIG OUT (+)

RS232

Console port – communication interface for calibration, connection to PLC

RS485

Modbus interface

All wiring and maintenance on the KAM LRW must be done in accordance with regional and classification

requirements. It is the user's responsibility to understand these requirements.

It is also recommended that the LRW be wired with flexible wiring/conduit with additional slack/length in the

wire to accommodate insertion, removal, and testing.

To avoid repeatedly opening electronics enclosure during diagnostics, it is recommended operators permanently

wire an RS232 connection to the instrument with corresponding 9-pin connection at junction box for PC

connection.

Operators should take all possible precautions to avoid any moisture from entering the electronics enclosure.

The enclosure should not be left open in inclement weather or for long periods of time, especially during

operation, as condensation will accumulate. All conduits should be sealed and secured in accordance with re-

gional and classification requirements, and unused 3/4" NPT openings should be sealed with provided plug. Do

not power wash the unit.

If necessary, disconnect LCD connector in order to access wiring terminals. The LRW supplies power for the

loop. Make sure the device that receives data from the LRW does not have a power source of its own switched

on. Also, the LOOP+ and LOOP- are isolated inputs from the chassis/earth. Do not connect either to a common

ground. Use an isolator if necessary.

INPUTS/OUTPUTS/SERIAL