−

50

−

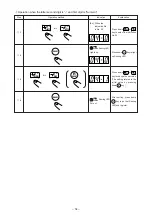

No.

State at the time of delivery

2,500 r.p.m.

200 r.p.m.

600 r.p.m.

1,000 r.p.m.

2,500 r.p.m.

2,500 r.p.m.

No. 50 : 1

No. 51 : 1

No. 52 : 1

0

0

0

0

0

0

Solenoid type : 0

Pneumatic type : 3

1

0

+X : 50

-X : 50

+Y : 30

-Y : 30

2

2

0

Setting range

200 to 2,500 r.p.m.

1st stitch : 200 to 900

2nd stitch : 200 to 2,500

3rd stitch : 200 to 2,500

4th stitch : 200 to 2,500

5th stitch : 200 to 2,500

Pattern No. 50 to 52 can be

individually set.

0 : Ineffective

1 : Effective

0 : OFF

1 : ON (Key lock)

0 : Production counter

1 : Bobbin thread counter

0 : Up position stop (53˚)

1 : Upper dead point stop (0˚)

0 : Origin

1 : Sewing start point

0 : No

1 : Yes

0 : No

1 : Yes

0 : 1 pedal

1 : 2-step pedal

2 : 1 pedal (PK-57)

3 : 3-step pedal (right precedence)

4 : 3-step pedal (left precedenc)

5 : 3-step pedal (no precedence)

0 : No

1 : Yes

0 : Lifting

1. : Prohibited

X : 0 to

±

50

Y : 0 to

±

30

(Unit : 1 mm)

0 : Ineffective

1 : Operation panel reset key

2 : Machine head switch

0 : 161˚ Slow

1 : 149˚

2 : 137˚

3 : 125˚ Fast

0 : Yes

1 : No

Function

Setting of upper limit of sewing speed

(Setting in unit of 100 r.p.m.)

Setting of soft start speed

(Start-up speed of 1st to 5th stitch at sewing start is set

in unit of 100 r.p.m.)

Setting of calling service pattern data

Selection of key lock mode

X/Y scale, display of max. speed limitation, and whether

to change can be set. (Prevention of maloperation)

Selection of counter action

Production counter : adding counter

Bobbin thread counter : subtracting counter

Selection of needle bar stop position

Upper dead point stop : After up-position stop, needle

bar rotates reversely and stops near its upper dead

point. (Stop position is higher.)

Selection of reference point of enlargement/reduction

Whether to execute origin retrieval after completion of

sewing (When sewing with normal pattern No.)

Whether to execute origin retrieval after completion of

sewing (When sewing with cycle pattern)

Selection of pedal specifications

Selection of output of wiper solenoid

Selection of prohibition of presser lifting after completion

of sewing

Setting of range of feed travel limit

(Setting separated in domains of +X, -X, +Y, and -Y)

Selection of input of midway stop switch

(When selecting panel reset key, input of midway stop

is performed only during sewing operation.

Selection of feed timing

When thread is not well-tightened, set 1 or 0 to increase

effect. (Main shaft angle sets start of feeding.)

Selection of control of simultaneous jump feed with

thread trimming (Normally, use 0.)

Level

U

U

U

U

U

U

U

U

U

U

U

S

S

U

U

S

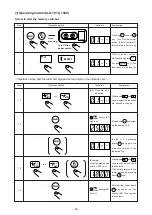

5. MEMORY SWITCH (LK-1910, 1920)

™

Purpose of the memory switch .... The memory switches are able to set the various performance of the sewing machine by means

of programming. The contents are separated in the user level (U) and the service level (S).

™

List of items of memory switches