−

6

−

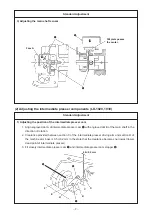

Adjustment Procedures

Results of Improper Adjustment

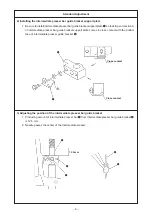

1) Push counterweight

1

to main shaft front bushing

2

, insert a

clearance gauge of 0.5 mm between main shaft intermediate

bushing

3

and thrust collar A

4

and fix thrust collar A

4

with

screw while pressing it to main shaft intermediate bushing

3

side.

2) Remove the clearance gauge and fix thrust collar B

5

so as to

lightly insert main shaft intermediate bushing

3

between thrust

collar A

4

and thrust collar B

5

.

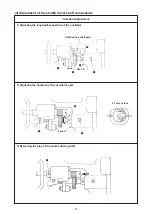

1) Making the clearance between servo motor

1

and the coupling

0.5 mm, fit screw No. 1

4

to the flat section. Then install the

motor.

2) Insert rubber ring

3

(RO1524240100) between main shaft rear

bearing

2

and the coupling. making the clearance between

the main shaft rear bearing and the coupling 2.5 mm, fit screws

No. 1

4

to the flat section. Then install the motor.

(Caution) When engaging the respective couplings, be sure

to align the two positions of the screws in the

direction of rotation.

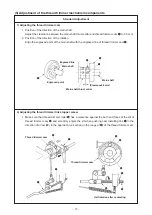

™

If the position of the couplings is

not correct, the main shaft does

not stop at the normal angle.

™

If the installing clearance of the

couplings is plus, the moving

clearance of the couplings in the

axial direction is lost, and a

torque is applied to the main

shaft.